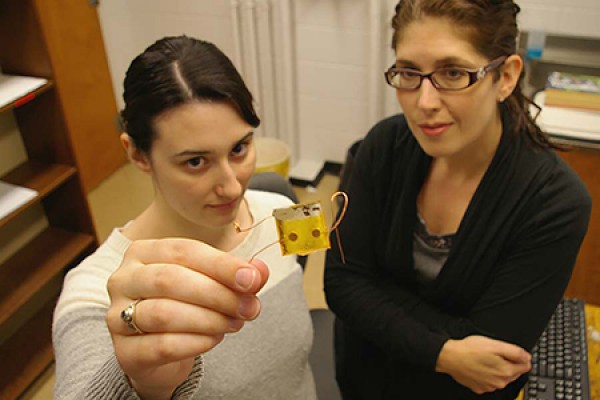

Researchers Heather Filiatrault and Tricia Carmichael have found a way to bridge cracks inherent in stretchable electronic materials.

Researchers Heather Filiatrault and Tricia Carmichael have found a way to bridge cracks inherent in stretchable electronic materials.

A UWindsor research team has found that working with a problem, instead of against it, can result in incredible breakthroughs. Chemistry professor Tricia Carmichael and co-investigator Heather Filiatrault have successfully created stretchable electronics able to continue conducting electricity even after stretching to the point of cracking.

Stretchable light-emitting devices are the building blocks of foldable and expandable display screens and electronics-integrated clothing, as well as other soft devices designed to go inside a body, like a stretchable balloon catheter that can mend damaged areas of the heart.

“The dilemma with the design of these devices is that when we use electrically conductive materials, like aluminum or copper, these materials will crack when stretched even a minimal amount,” says Dr. Carmichael (BSc 1992, PhD 1996).

Stretchable electronics integrate a thin film of electrically conductive material with a film of rubber, but the conductive materials crack when they are stretched, which breaks the circuit and renders the device useless.

Carmichael and her lab team investigated the theory that when a rough surface is stretched it generates multiple micro-cracks, instead of a few large debilitating cracks. To manipulate the cracking, she simply added a layer of inexpensive white glue before the thin sheet of metal was attached.

“Instead of eliminating cracks, we encouraged a lot of cracking, like a spider web of cracks that don’t form a continuous pathway through the sheet,” says Carmichael. “The cracks purposefully interfere with each other, relieving the strain, so the current can flow along a jagged but continuous pathway.”

The glue layer is watered down to control the film thickness. It is spread over the rubber layer and creates the required roughness by forming blobs. Members of Carmichael’s lab built a strain sensor out of rubber, glue and gold and wrapped it around a thumb. The sensor successfully monitored when the digit was extended, and when it was not.

Carmichael says this is a low-cost, green solution, which uses simple components that could potentially scale up to larger surface devices.

“We made the system more defective in order to make it work better,” she says. “I love this concept of embracing the natural tendency of cracking, and then pushing it further.”

This research is published as the cover story in the latest edition of ACS Applied Materials & Interfaces. The article, A Self-Assembled, Low-Cost, Microstructured Layer for Extremely Stretchable Gold Films, is authored by Carmichael, Dr. Filiatrault (BSc 2009, PhD 2015), Stephen Carmichael (BSc 1989) and Rachel Boutette (BSc 2015).