This guest column by Dr. Ofelia A. Jianu, an assistant professor in UWindsor’s Mechanical, Automotive and Materials Engineering Department, is featured in the 2019 issue of Windsor Engineering (WE).

This guest column by Dr. Ofelia A. Jianu, an assistant professor in UWindsor’s Mechanical, Automotive and Materials Engineering Department, is featured in the 2019 issue of Windsor Engineering (WE).

There are 35.11 million vehicles registered in Canada out of which 12.55 million are registered in Ontario. Simultaneously, Canada’s population is 37.59 million out of which Ontario hosts 14.57 million people. This might all look good in terms of the economy; however, it is troubling when you consider that eight molecules of CO2 are released for every molecule of burned gasoline in an internal combustion engine. That translates to the average vehicle emitting approximately 4.6 metric tons of CO2 per year.

In 2005, automotive pollution was responsible for 20 per cent of the European Union’s CO2 emissions, roughly 60 per cent of which can be attributed to private automobiles. The EU legislation has set mandatory emission reduction targets for new cars in order to meet the targeted 95 grams of CO2 per kilometer by 2021, a significant drop from the 130 grams per km recorded in 2015. Still, this is not sufficient, and hydrogen may be a possible solution. Hydrogen can have a significant role in providing better environmental sustainability as it combusts clean in the presence of oxygen and the output is water. Sounds great, right? So, why are we not using hydrogen as fuel yet?

Well, although hydrogen is the most abundant element in the universe, filling stars and gas planets, it seldomly exists in its natural free state on Earth. Hydrogen strongly bonds to other elements, such as oxygen, to form water and vast amounts of energy are required to separate it. Additionally, hydrogen is only as clean as the method used to produce it. Currently the most common methods of hydrogen production are reforming fossil fuels in the presence of steam in processes such as steam methane reforming (SMR), coal gasification and partial oxidation of heavy oil.

The steam methane reforming method is the cheapest, but it releases carbon monoxide. You might have heard of “blue” hydrogen, which is produced via SMR and is not as bad for the environment as other methods of production, labeled “grey.” At the University of Windsor in the Alternative Fuels and Energy Laboratory (A-FuEL), we are striving to create “green” hydrogen: the purest, cleanest hydrogen produced using sustainable methods not based on fossil-fuels.

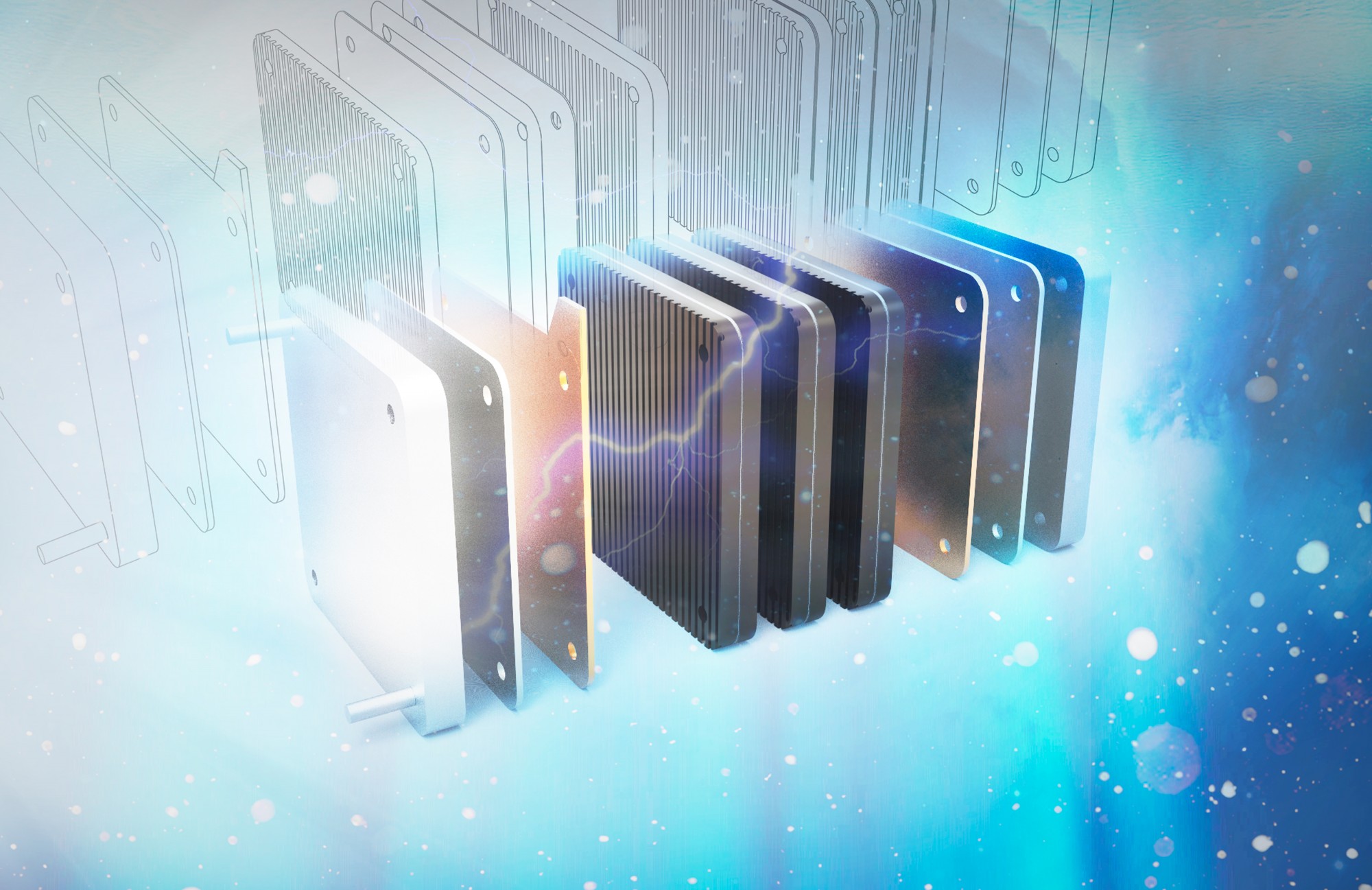

Some clean methods we are exploring are water electrolysis, thermochemical water decomposition, photochemical, photoelectrochemical and photobiological. Hydrogenics Inc. based in Mississauga, Ont. and Ballard, in Burnaby, B.C., are two internationally recognized manufacturers of water electrolyzers and fuel cells (electrolyzers operating in reverse). Other clean methods to produce green hydrogen are thermochemical cycles for water decomposition.

Thermochemical cycles split water into hydrogen and oxygen through a series of chemical reactions by recycling the constituents internally. The advantage is that they are capable of producing large amounts of hydrogen without releasing pollutants into our environment, while

using waste heat from industrial emitters to drive the reactions. It would be no surprise if hydrogen production plants were erected next to nuclear power plants (waste heat at 450 ºC), cement plants (waste heat at 1,200 ºC) and foundries, to name a few.

This hydrogen research performed in A-FuEL is especially beneficial to Windsor considering Ontario’s and USA’s efforts to adopt hydrogen as a clean fuel. As a border city, Windsor is well positioned to become the “green” hydrogen generation hub, connecting the Greater Toronto Area and the United States. In A-FuEL, we produce the fuel of the future, so your wheels can keep on turning.