Two UWindsor engineering researchers have received more than $715,000 in federal funding to bring cutting-edge artificial intelligence to the manufacturing floor.

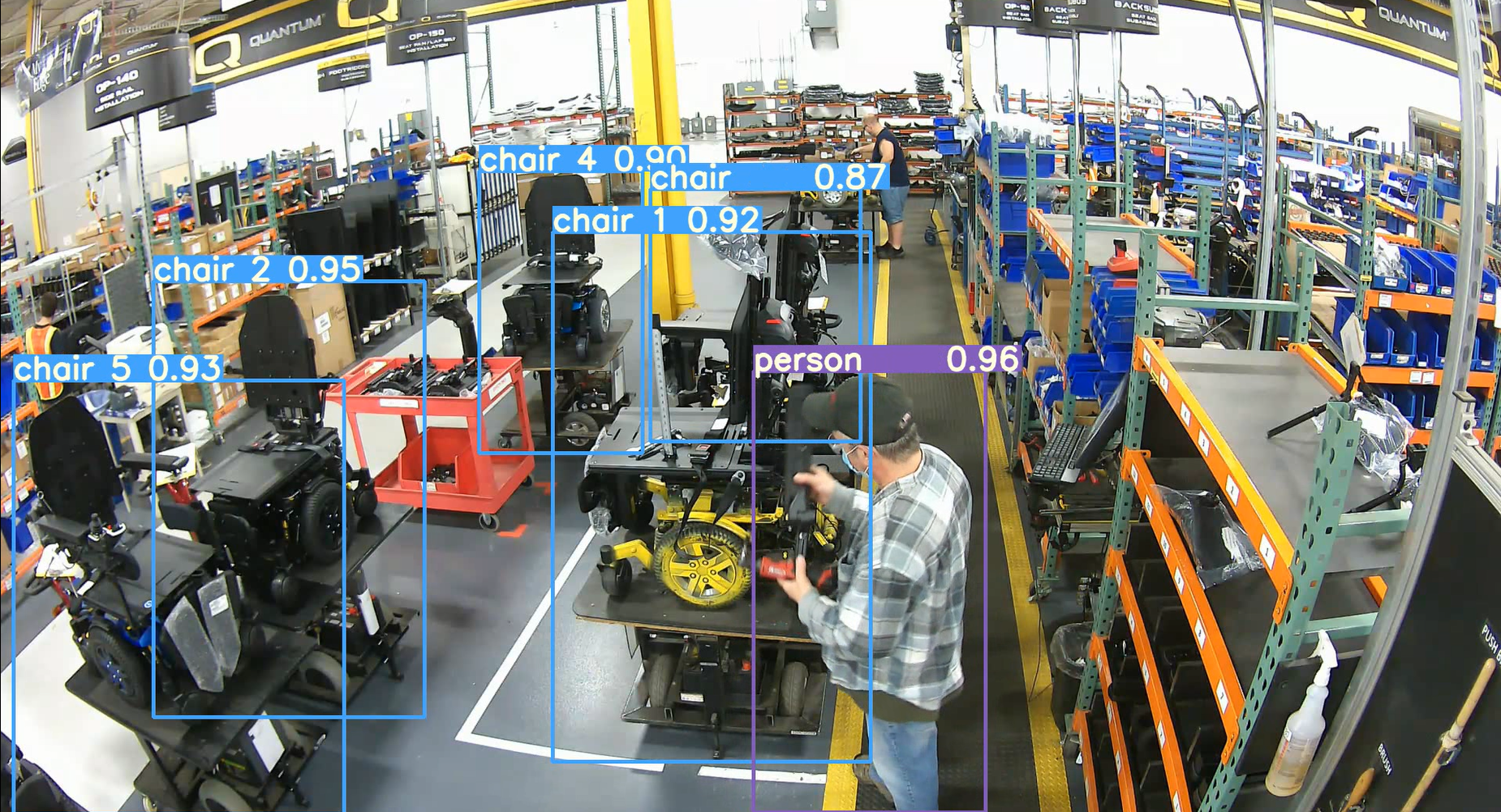

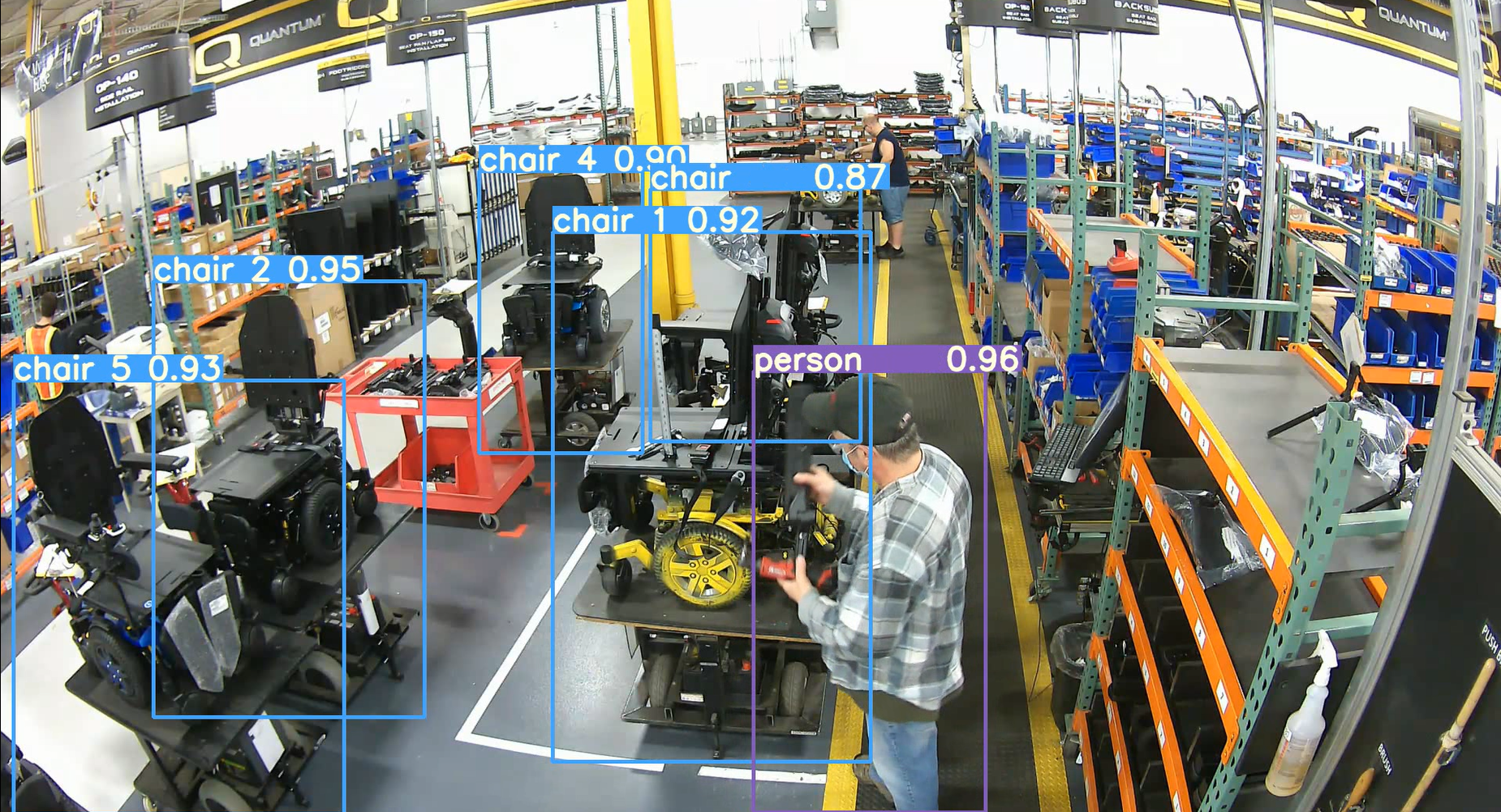

Professors Jonathan Wu and Afshin Rahimi say they can mitigate human error and maximize productivity in manufacturing plants through advanced computer vision.

“Human errors were the major driver behind $22.1 billion in vehicle recalls in 2016,” says Dr. Wu, a former Canada Research Chair in Automotive Sensor and Information Systems.

He and Dr. Rahimi aim to create a smart production assistant that will help manufacturing plant operators gain unprecedented visibility into their manual production operations, allowing them to optimize their worker efficiency while maximizing productivity. They will achieve this by automating data generation using computer vision, converting raw data into useable information, visualizing information using common business intelligence methodologies and prediction of future.

The professors have received $717,450 of support from the Mitacs Accelerate program and additional support from Smart Computing for Innovation (SOSCIP) in partnership with i-5O, an early stage Silicon Valley based start-up that has developed a proprietary computer vision powered digital twin to help manufacturers track, measure, and improve their manual production processes. Headquartered in San Francisco with operations in Toronto and Windsor, the company works with large Fortune 500 manufacturers in North America and Asia.

Khizer Hayat, chief innovation officer of i-5O, says its collaboration with Wu and Rahimi will bring the latest in artificial intelligence for improving human performance to the manufacturing industry.

— Published on Dec 20th, 2020

The Canadian Minister of Foreign Affairs met with engineering students and faculty Tuesday to learn about industrial automation and manufacturing innovations taking place at the University.

Chrystia Freeland visited the Ed Lumley Centre for Engineering Innovation to meet with faculty and students who specialize in mechatronics, 3D printing, metal forming, and electric vehicles.

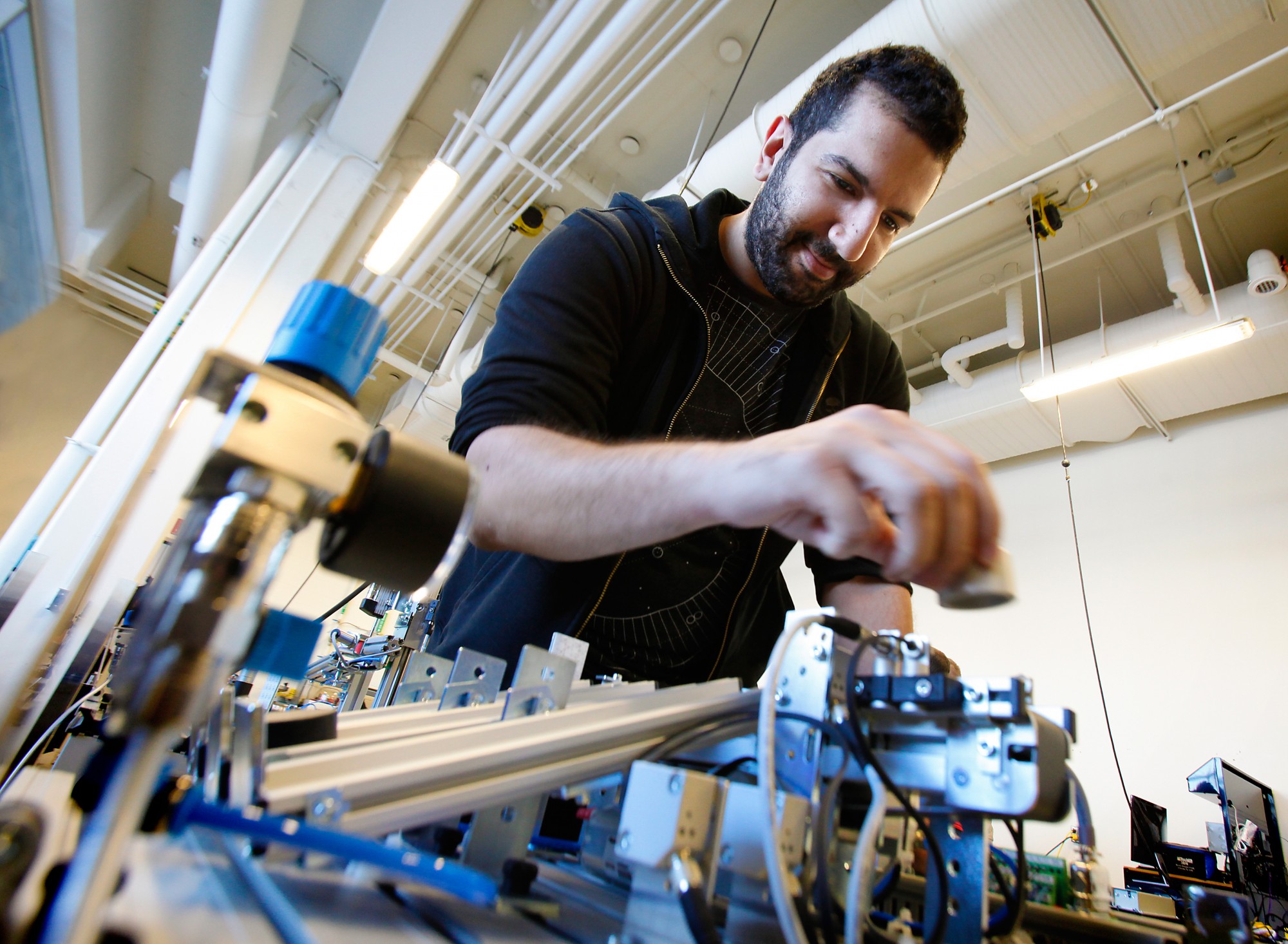

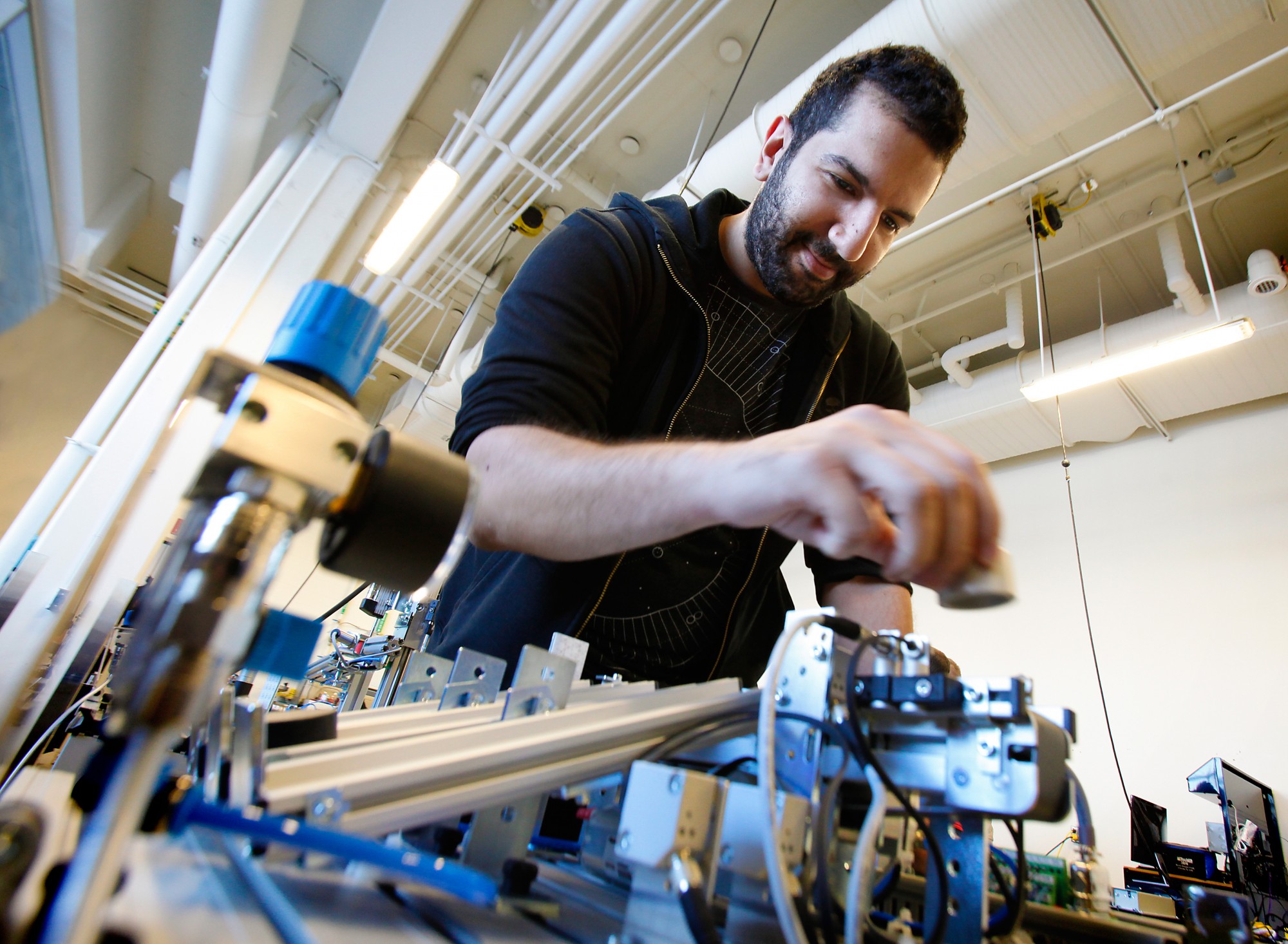

Mohammad Anvaripour, a PhD candidate in electrical and computer engineering, showed Freeland how he is developing complex systems to prevent collisions and improve collaboration between humans and robots in automated workplaces, such as an automotive assembly plant.

Doctoral candidate Hamed Kalami presented a cost-effective, 3D-printable hand brace he designed to assist people with connective tissue disorders.

— Published on Nov 21st, 2018

UWindsor researchers and students will share more than $6 million of more than $558 million in Discovery research funding announced Tuesday by Kirsty Duncan, federal minister of science and sport.

Duncan visited the University of Windsor campus to announce the funding as part of the government’s plan to attract global talent, promote diversity, and provide nearly 4,300 researchers and students across Canada with the means to pursue world-leading discovery work.

UWindsor interim president Douglas Kneale said the announcement provides a major boost to the advancement of science and engineering.

“Whether one’s area of research is a singular endeavour or a team effort, whether it’s curiosity-driven or hands-on applied, this investment in researchers at the University of Windsor and elsewhere will pave the way to untold discoveries,” he said.

UWindsor boasts nearly 30 Discovery Grants recipients focused on research in such areas as advanced manufacturing and ecology.

— Published on Jan 5th, 2021

The multidisciplinary field of mechatronics integrates mechanical, electrical, and computer engineering to design and implement complex engineering and manufacturing systems.

A new collaboration with global tech giant Siemens has enabled the University of Windsor to launch a world-class industry certification in mechatronic systems.

The weekend Siemens Mechatronic Systems Certification Program focuses on key industrial skill areas such as electrical components, sensors, motor controls, programmable controllers, hydraulics, and pneumatics. In addition to teaching the technical knowledge, the program also stresses trouble-shooting and system-based technical thinking via hands-on training.

— Published on Jul 4th, 2018

High academic performances and leadership skills landed 21 University of Windsor engineering students scholarships from the Ontario Professional Engineers Foundation for Education.

Asif Khan, chair of the Windsor-Essex chapter of Professional Engineers Ontario, awarded students on behalf of the foundation during a ceremony at the Ed Lumley Centre for Engineering Innovation for recipients who received scholarships in the past three years.

“For me, the most significant benefit has been that the financial support has allowed me to fully dedicate my time and energy into succeeding in my studies,” said Steven Vrantsidis, a recipient of the foundation’s $1,500 Entrance Scholarship.

The Ontario Professional Engineers Foundation for Education (OPEFE) is a charitable foundation run by a volunteer board of directors that provides scholarships to encourage engineering students to pursue careers in the profession. The scholarships are financed through donations from professional engineers in Ontario, as well as corporate and individual donations.

— Published on Jan 7th, 2021

The Windsor Section of the Institute of Electrical and Electronics Engineers (IEEE) Canada has been recognized for its leadership and networking events.

The IEEE Windsor Section, led by University of Windsor researchers, received IEEE Canada’s Exemplary Section Award for small sectionsfor its 2017 activities, leadership, management and administration.

Esrafil Jedari, vice-chair, IEEE Windsor Section and UWindsor research assistant in the Department of Electrical and Computer Engineering, said the section was recognized for hosting around 30 technical, professional and social events on campus; its large network of volunteers and growth in memberships; and organizing and hosting the 30th Annual Canadian Conference on Electrical and Computer Engineering (CCECE 2017).

The group has grown steadily since it branched out on its own as the 21stsection in Canada in 2014 after operating as a student branch for two years within the Southeastern Michigan Section. The majority of its 306 members — which includes industry from the Windsor-Essex region— are University of Windsor faculty and students. The Windsor Section has three technical joint chapters for six IEEE professional societies, a University Windsor student branch and two affinity groups: Young Professionals and Women in Engineering.

— Published on May 22nd, 2018

Several University of Windsor engineering students and alumni were honoured during a local celebration of the engineering profession.

Windsor’s Engineering Month Committee hosts an annual awards luncheon to “bring public awareness to the diversity and importance of the exciting fields of engineering and technology and invite prospective students to consider these professions,” said Tina Hawco, chair of the Engineering Month Committee.

The committee is comprised of engineers and technologists from local municipalities, consulting engineering firms, the University of Windsor, St. Clair College, professional associations and industry.

Priscilla Williams, a PhD candidate in the civil and environmental engineering department, Michael Cappucci, BASc ’11, and Aaron Blata, BASc ’14, were named the Top Three Under 30 during a ceremony April 13, 2018 at the Fogolar Furlan Club for demonstrating higher than average abilities to undertake engineering projects, outstanding work ethic and leadership early in their careers.

— Published on Jan 7th, 2021

A new weekend technology program offered by the University of Windsor is helping local companies meet market demands.

The Bachelor of Engineering Technology (BEng Tech) degree, originally designed to create a pathway from college to university, is now available on weekends for working professionals to expand their expertise in mechatronics, industrial automation, robotics, manufacturing and engineering operational functions.

“Companies heard about this and expressed a great deal of interest,” said Dr. Mehrdad Saif, UWindsor’s dean of engineering. “We thought why not do it on weekends for these types of students and put in place more courses around the theme of mechatronics and industrial automation. As an engineering school in Windsor, we have an obligation to meet the needs of the community and industry.”

— Published on Jan 7th, 2021

A design competition for electrical engineering students brought their learning out of textbooks and into reality last week.

A design competition for electrical engineering students brought their learning out of textbooks and into reality last week.

“It was interesting to apply the theory we learned in class to predict circuit behaviour and help troubleshoot,” said Emilie Bondy, whose team took home first place for designing a Multiple Option Input Responsive Beverage Mixer.

Bondy and her teammates, Muntasir Alam and Tristen Michaud-Laughton, received $180 in UWindsor Campus Bookstore gift certificates.

More than 100 electrical engineering students from professor Mitra Mirhassani’s third-year class, “Electronics II,” competed. As part of a course requirement, students were tasked with designing a product under a $30 budget using an analog circuit and various signal processors.

— Published on Dec 7th, 2017

An injection of nearly $2 million in federal funds will aid University of Windsor researchers like Daniel Green, who is helping automakers incorporate lightweight sheet materials into their vehicles.

The automotive sector is turning to lightweight materials as an alternative to steel to improve fuel efficiency. However, lower-density metals tend to have limited formability, says Dr. Green, an associate professor who specializes in materials engineering.

“Innovative forming processes need to be developed and optimized for the production of automotive parts,” he said. “With high-speed forming, we can get 100 per cent more formability than we can with conventional stamping.”

Green is one of 14 UWindsor engineering professors who was awarded funding through the 2017 Discovery Grants Program — an annual competition run by the Natural Sciences and Engineering Research Council of Canada (NSERC) to advance research in Canadian universities.

— Published on Jan 7th, 2021

A design competition for electrical engineering students brought their learning out of textbooks and into reality last week.

A design competition for electrical engineering students brought their learning out of textbooks and into reality last week.