A screenshot shows the Ed Lumley Centre for Engineering Innovation students created in Minecraft.

The University of Windsor Engineering Students’ Society is bringing campus to the screens of students learning from home.

The society has created a replica of the University of Windsor campus on Minecraft — a video game that allows you to create a virtual world with Java programming.

Students can explore each floor of the Ed Lumley Centre for Engineering Innovation and take a stroll through UWindsor’s campus peppered with lush trees, flower beds and even its Promise campaign billboards.

“Since we are all stuck inside on our computers for the remainder of the semester, it’s important to keep the sense of campus community,” says Theo Sancartier, president of the Engineering Students’ Society.

“With this Minecraft server, we hope to have students interacting in a way no one thought of before.”

Sancartier says the society’s executive committee and other volunteers spent the entire summer creating the server to ensure incoming students had a memorable experience and felt connected to campus.

— Published on Mar 15th, 2021

Zac Sinasac, just finishing his first semester of graduate study in automotive engineering, is grateful for the opportunities he has been afforded.

“I say thank you as much as I can to the people who have supported me,” he says, listing faculty, family, friends — and donors to scholarships for UWindsor students.

Sinasac says the $1,000 Shawn Yates Memorial Award helped inspire him to excel.

“It’s a motivation, because you’re being rewarded and recognized for your efforts,” he says. “Sometimes you’re so deep in your books that you don’t realize people take notice.”

He made the effort to learn more about Yates, a UWindsor alumnus (BASc 1982, MBA 1992) who helped to found the Windsor Engineering co-op program with the Fiat Chrysler Automobiles’ Automotive Research and Development Centre (ARDC) before his death in July 2017.

— Published on Dec 20th, 2020

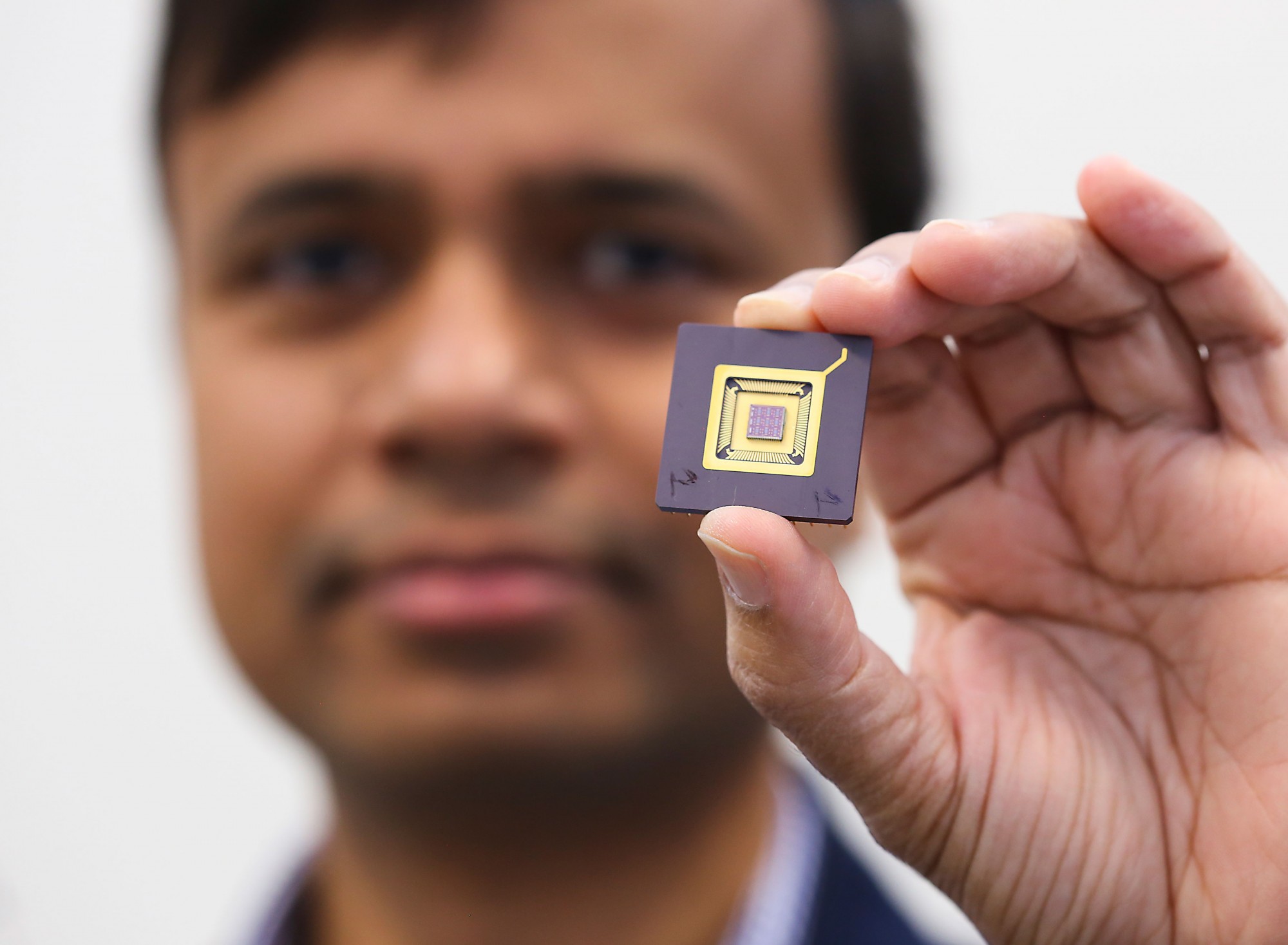

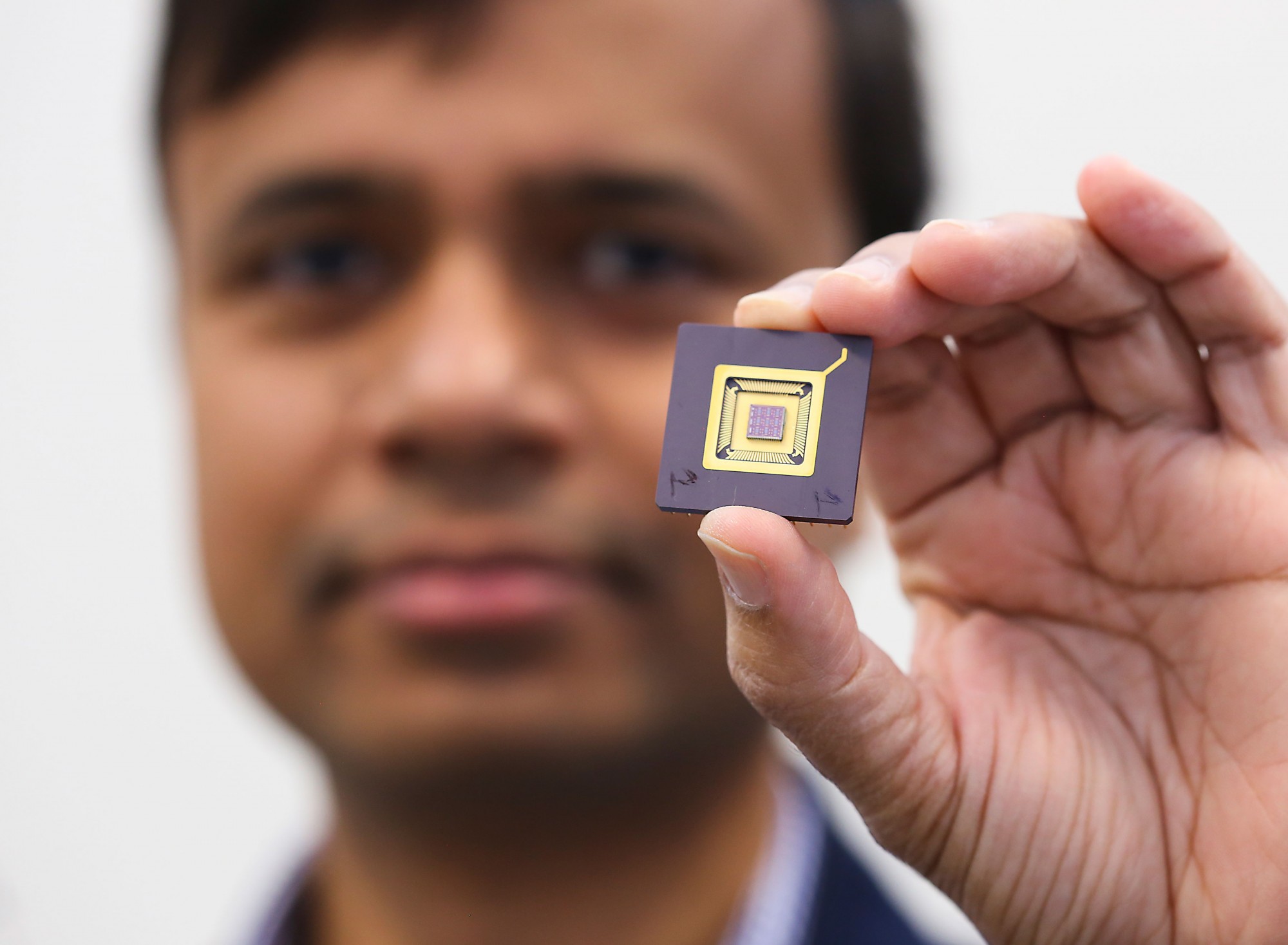

A University of Windsor engineering professor is turning to nature to inspire his research. Dr. Jalal Ahamed and his team in the Micro Nano Mechatronic Research Lab are working on technologies that replicate the stabilizing, rapid wingbeats of a bee and the echoes bats use to navigate and forage.

The research group has designed a microchip with microscopic wings that flap at high speeds at a set frequency when electrical wires apply voltage. When a change in orientation or motion is detected, the thin, gold-coated, silicon wings will alter their flapping speed.

— Published on Jan 5th, 2021

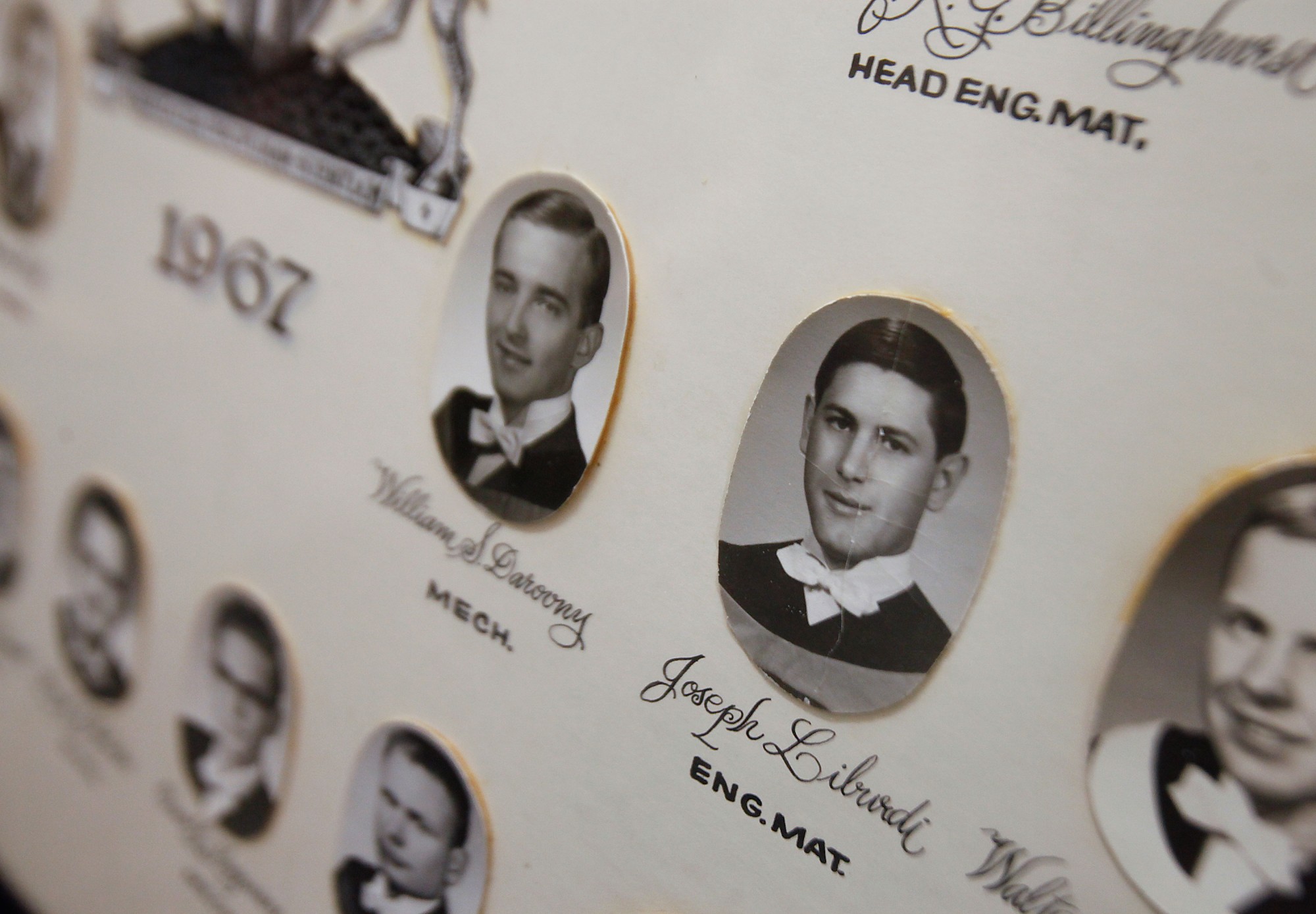

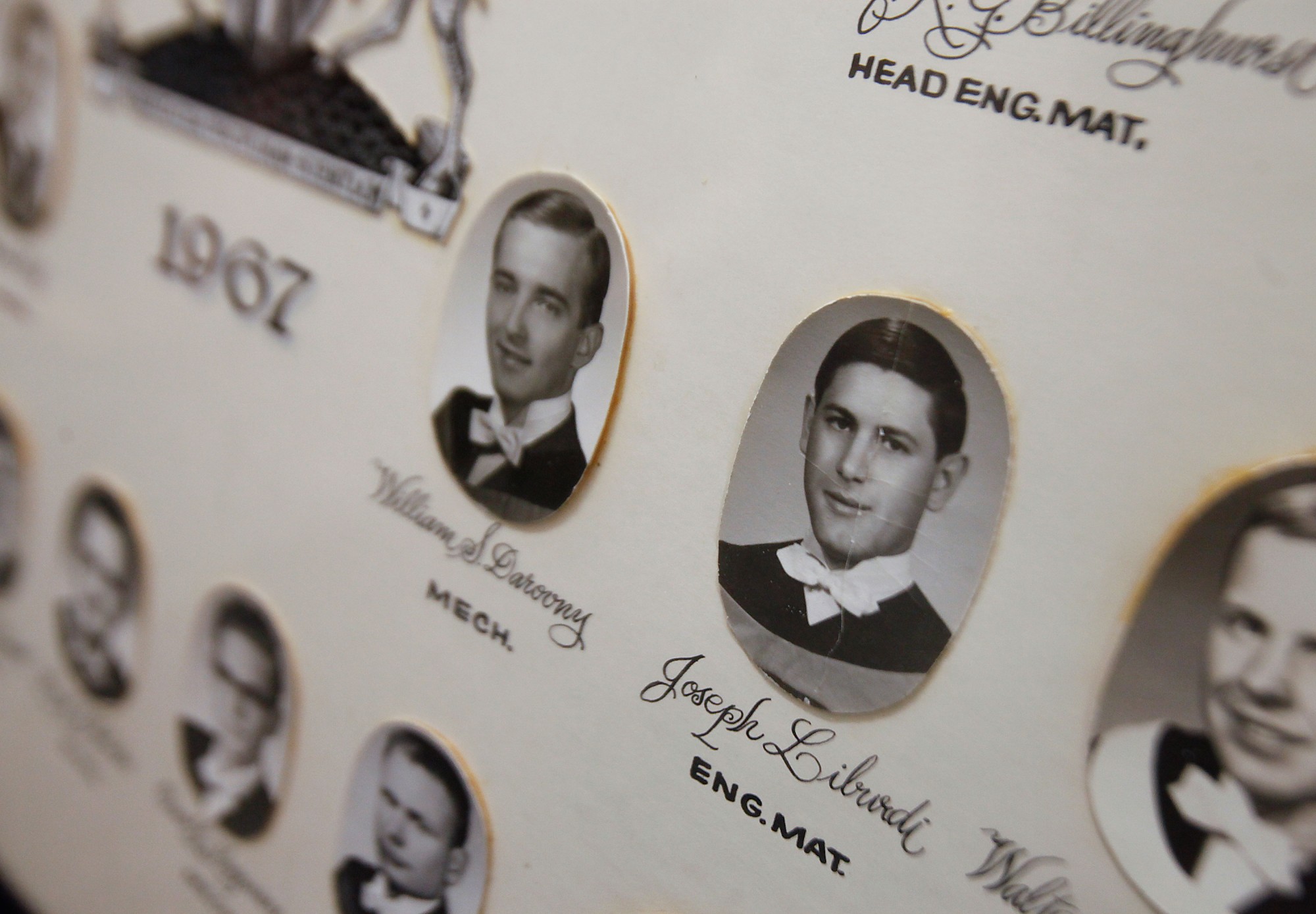

As an engineering student at the University of Windsor, Joe Liburdi honed his multi-disciplinary skills and acquired his technical confidence. Now, as the president of his own global enterprise, Liburdi wants to ensure future students have the opportunity to follow in his footsteps.

“The University of Windsor’s challenging multi-disciplinary materials program and one-on-one attention with my professors gave me the tools I needed to establish Liburdi Engineering Limited as an innovative technology leader in global markets,” says Liburdi BAsc ’67, who produces advanced welding and coating systems for turbine, aerospace and power generation components.

“They challenged me to always be the best.”

— Published on Jan 5th, 2021

Pamela Nadin-Mcintyre was introduced to the importance of innovation and its role in business at a young age.

As a daughter of a Windsor tool and die business owner, she remembers watching her dad brainstorm and execute countless ideas to drive business and stay competitive.

Decades later and three provinces away, she is the innovation lead — in addition to safety, technical safety, and risk management — for Canada’s largest independent crude oil and natural gas producer, Canadian Natural Resources Limited (Canadian Natural).

“My dad’s the one who really helped push me in this direction,” says Nadin- McIntyre BASc ’86.

In addition to ensuring the right systems are in place to maintain the safety of people across Canadian Natural’s operations, she leads dedicated teams that are focused on improving the company’s environmental performance through technology and innovation. And for someone who is passionate about the environment, it’s more than just a job.

— Published on Jan 5th, 2021

More than 100 industry and community members came to the University of Windsor Friday to learn more about student engineering projects that have real-world applications and the potential to advance technology.

The fourth-year capstone projects ranged from fitness-based wearables, autonomous vehicle technologiesand sensor systems for monitoring greenhouses to the optimization of the Chatham Water Pollution Control Plant and building energy retrofitting.

"Our project allowed us to explore a variety of practical solutions to real-world problems,” says Olivia Byrne, whose team placed second in the Water Environment Association of Ontario's annual student design competition for its optimization of the Chatham Water Pollution Control Plant. “Coming up with a competitive solution required intense dedication and organization.”

— Published on Jan 5th, 2021

A team of mechanical engineering students placed fifth in the world's largest intercollegiate rocket engineering competition.

The Spaceport America Cup attracted 121 teams worldwide to compete June 18 to 22, 2019 in Las Cruces, New Mexico. University of Windsor Rocketry Team member Katarina Berg says the competition has multiple categories based on motor type and either a target altitude of 10,000 or 30,000 feet. The UWindsor team chose to compete in the 30,000 commercial off the shelf motor, solid propulsion category against 19 teams.

“We came in fifth in our category and 31st in the overall competition. Our actual apogee was 26,517 feet,” Berg says. “It was absolutely an amazing experience to be able to connect with and learn from universities all over the world. To see all the different approaches to the same common problem is very intriguing.”

— Published on Dec 20th, 2020

A new History Channel show about the world’s most fascinating and inexplicable mysteries featured a University of Windsor engineering professor and his investigation into one of Windsor’s infamous enigmas — the Windsor Hum.

The intermittent rumbling sound has plagued local residents for the past seven years. In 2013, Colin Novak, an associate professor in the mechanical, automotive, and materials engineering department, was contracted by the Government of Canada to lead a study on the source of the hum.

A Los Angeles film crew from UnXplained, a show hosted and produced by William Shatner, visited campus to learn more about Dr. Novak’s Noise Vibration and Harshness-Sound Quality Group, which set up low-frequency noise monitoring stations across the city’s west end and portable infrasound arrays to record noise within the hum’s frequency range.

— Published on Jan 5th, 2021

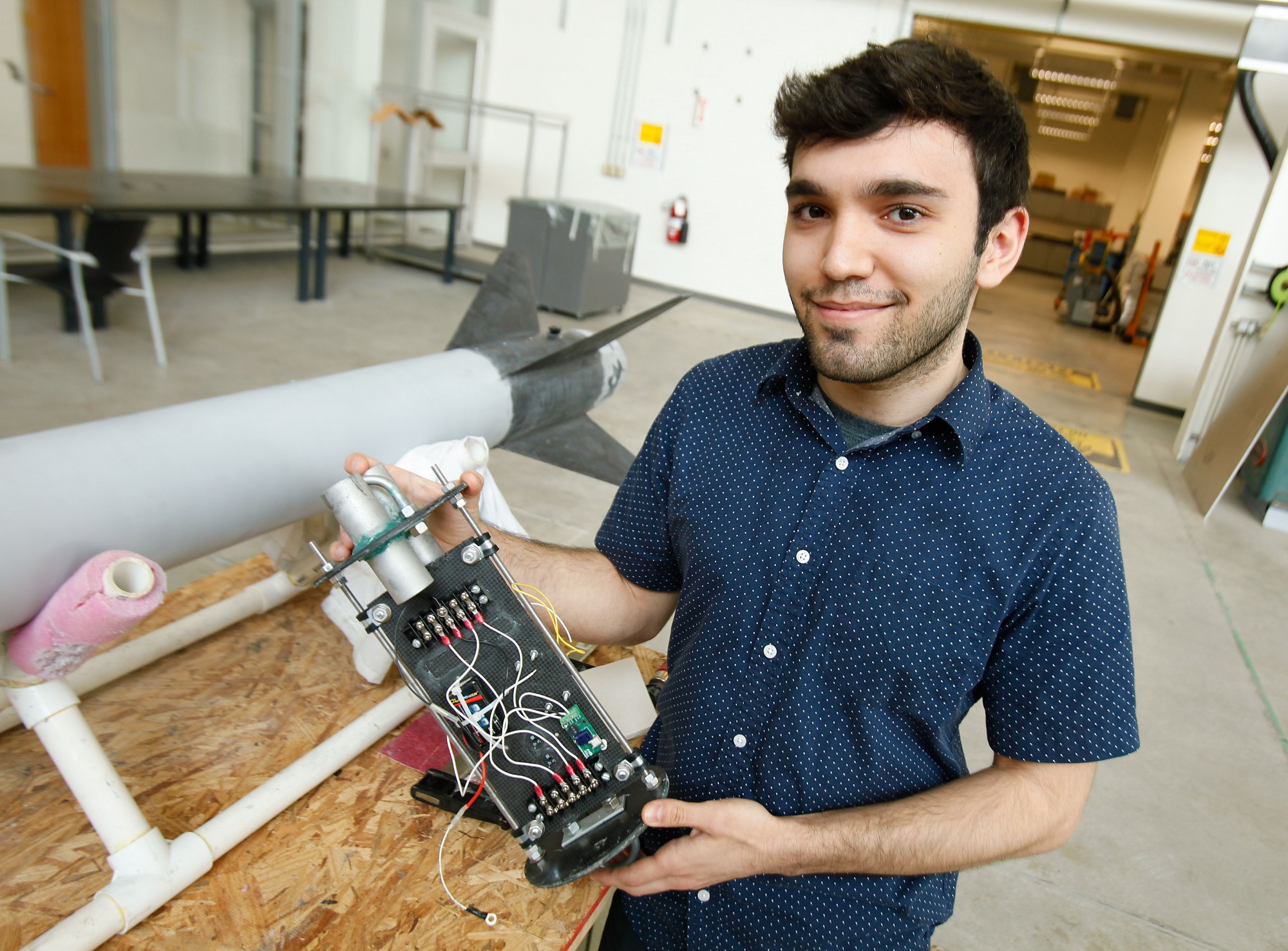

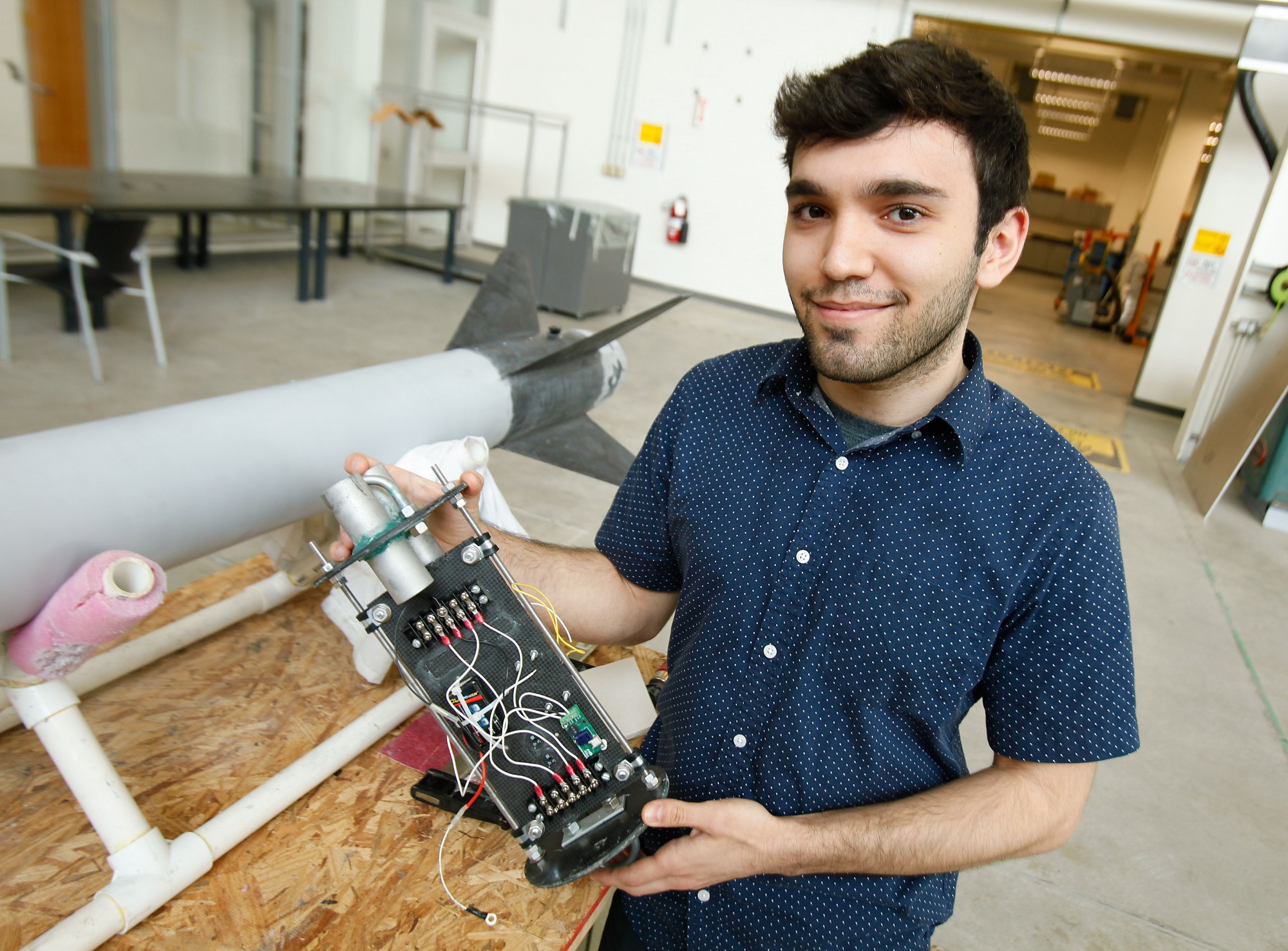

A UWindsor student studying aerospace engineering is one of four province-wide to receive an Ontario Aerospace Council scholarship.

Atilla Saadat, a third-year mechanical engineering student in the aerospace stream, received a $2,500 scholarship for academic achievement and his work outside the classroom. Saadat is the founder and space systems technical lead of the University of Windsor Space & Aeronautics Team (WinSAT), a multi-disciplinary group of more than 30 students building a space-ready 3U Cube Satellite for Low Earth Orbit to compete in the Canadian Satellite Design Challenge.

“His work has already demonstrated a tangible impact at UWindsor, as WinSAT aims to increase the space and aeronautics engineering opportunities at our institution,” says Afshin Rahimi, an assistant professor in the University’s Department of Mechanical, Automotive and Materials Engineering.

— Published on Jan 5th, 2021

Studying engineering at the University of Windsor has shown Faraz Talebpour his potential to make a difference.

A doctoral candidate in electrical and computer engineering, his work on a remotely controlled underwater vehicle can find immediate application on real-world challenges. It was one of more than 30 research projects displayed during an open house Friday in the Centre for Engineering Innovation.

Talebpour says his experience scuba diving has helped him to appreciate how pollution threatens aquatic ecosystems.

“Going under the water you see how we’re destroying that world,” he says. “This project can save the marine life that we have endangered.”

— Published on Jan 5th, 2021