-

Covers the spectrum of Product Definition and Design, Planning Support Functions, and Product Manufacturing.

-

Conducts research in Production Scheduling, Facility Layout Problem (FLP), Computer Aided Process Planning (CAPP), Reconfigurable Manufacturing Systems (RMS), Cellular Manufacturing Systems (CMS), Supply Chain Management (SCM), Inventory Control/Lot-sizing, Healthcare management, and Sustainable Design and Manufacturing.

-

Emphasizes on themes and newer notions and domains of manufacturing such as distributed, multitask, and reconfigurable manufacturing as well as state of the art computations and algorithms.

-

Capitalizes on application of Mathematical Programming and Non-traditional Optimization.

-

Has success stories implementing customized Decision Support Systems (DSS) for production scheduling, applying Discrete Event Simulation (DES) and lean manufacturing in healthcare, and following advanced hybridized design methodologies for development of innovative designs in the fields of construction and farming.

Research infrastructure

-

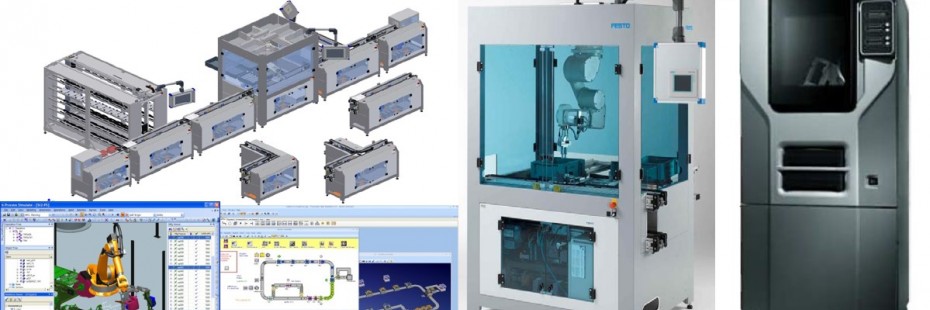

State-of-the-art transformable assembly system, a CNC Vertical Machining Center, fused deposition additive manufacturing machine, optimization suites (Xpress), state-of-the-art PLM solutions by Siemens PLM including NX, Teamcenter, and Tecnomatix, and simulation tools (Flexsim, Promodel, and AutoMod).

-

Has partnership with different industries in different sectors, which include Manufacturing, Agriculture, Construction, and Healthcare.

To get involved with the Production Operation Management (POM) Research Lab

Contact: Dr. Ahmed Azab

Department of Mechanical, Automotive and Materials Engineering

519-253-3000, Ext. 4958/5771

azab@uwindsor.ca

Visit uwindsor.ca/pomresearchlab for more information.