Mechanical and automotive engineering professor Peter Frise has received the UWindsor Alumni Excellence in Mentoring Award for his contributions to the development — personal, academic and professional — of students before and after their graduation.

“Mentoring must be continual chain of effort that extends throughout the relationships in one’s life,” says Dr. Frise. “This means that all senior people, in any organization, should reach out and play a role in helping junior people to succeed in their own careers. This is doubly true in a university such as ours — and that is why this award means so much to me.”

— Published on Jul 3rd, 2018

A reception Sept. 16 at the Ed Lumley Centre for Engineering Innovation honoured high-achieving researchers in the University of Windsor’s Turbulence and Energy Laboratory.

Several graduate students were recognized for their innovative research in addition to faculty and staff who assist with the operation of the Turbulence and Energy (T&E) Lab.

— Published on Jul 3rd, 2018

Derek O. Northwood, Distinguished University Professor and professor of engineering materials in the Department of Mechanical, Automotive and Materials Engineering, was inducted as a Fellow of the Royal Society of Canada in an awards ceremony on November 18 in Kingston, Ontario.

— Published on Jul 3rd, 2018

A team of engineering students has saved a local manufacturer thousands of dollars by suggesting improvements to shop floor production processes.

As part of their coursework, PhD candidates Maryam Shafiei Alavijeh, Danilo Stocco, Victor Eghujovbo and master’s candidates Alireza Pasha and Zahra Nazemi partnered with Lincoln Laser Solutions, a Windsor-based company that specializes in laser cladding and additive manufacturing, and found improvements that could save the company $30,800 annually.

“Part of the course requirement is for the students to complete a hands-on project where they must apply process improvement methods and tools learned in the class,” says professor Asif Khan, who teaches the class Lean Manufacturing and Process Improvement. “The focus of this group-based project is to study a process, identify waste and loss, find the root cause, and propose countermeasures to attack the loss.”

— Published on Jan 4th, 2021

Zac Sinasac, just finishing his first semester of graduate study in automotive engineering, is grateful for the opportunities he has been afforded.

“I say thank you as much as I can to the people who have supported me,” he says, listing faculty, family, friends — and donors to scholarships for UWindsor students.

Sinasac says the $1,000 Shawn Yates Memorial Award helped inspire him to excel.

“It’s a motivation, because you’re being rewarded and recognized for your efforts,” he says. “Sometimes you’re so deep in your books that you don’t realize people take notice.”

He made the effort to learn more about Yates, a UWindsor alumnus (BASc 1982, MBA 1992) who helped to found the Windsor Engineering co-op program with the Fiat Chrysler Automobiles’ Automotive Research and Development Centre (ARDC) before his death in July 2017.

— Published on Dec 20th, 2020

Companies are well aware of the environmental benefits of electrifying vehicle fleets, but how much is known about the security of these systems?

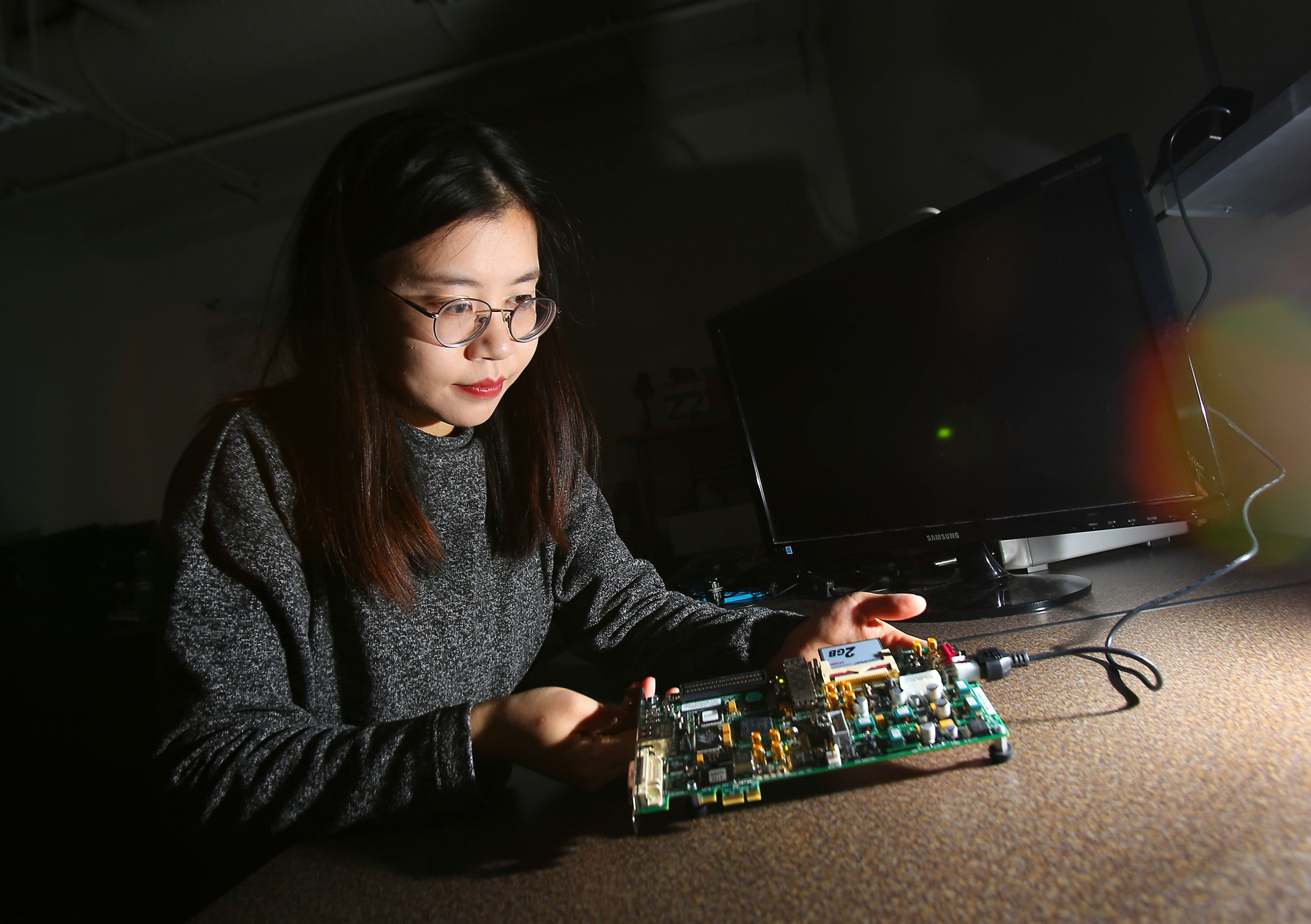

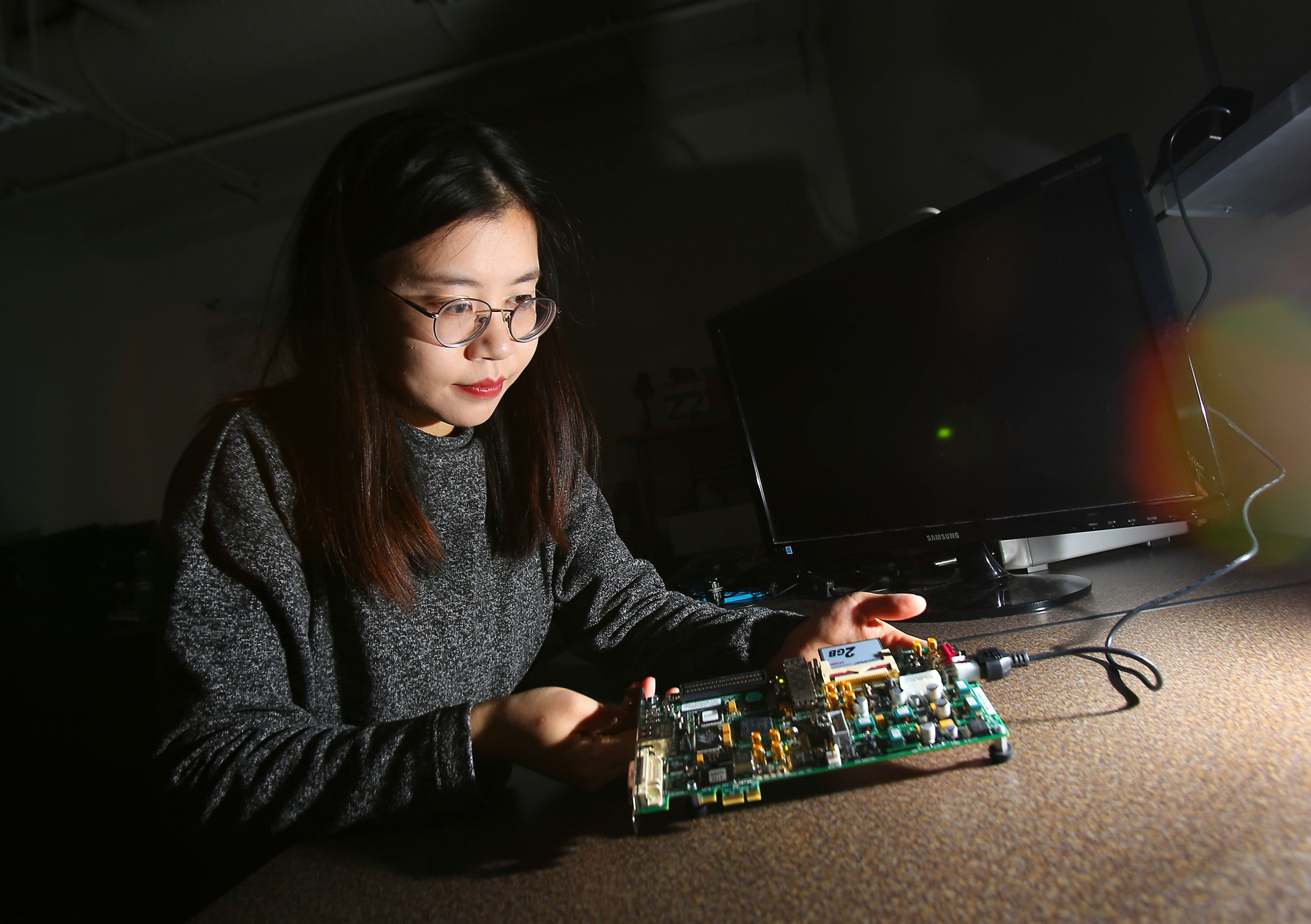

A University of Windsor researcher aims to dig deeper through the investigation of cybersecurity issues that arise when using electric vehicle fleets with battery charging infrastructure.

“The environmental, geopolitical and financial advantages of electric vehicles are well-studied and addressed in many research publications. However, security of these systems is not given the full attention that it requires,” says Dr. Mitra Mirhassani, the project lead and associate professor who specializes in electrical engineering.

Amazon announced in fall 2019 the largest order of electric delivery vehicles ever, according to David Clark, Amazon’s senior vice president of operations. The world’s largest retailer purchased 100,000 electric delivery vans from Rivian, a Michigan-based start-up. While companies like Amazon are making the switch to electric fleets, municipalities are preparing with plans to add infrastructure to accommodate the surge in consumer and corporate investments in alternative fuels. The City of Windsor is looking to set up 11 dual-port electric vehicle (EV) charging stations across the municipality, according to a 2019 city council report.

— Published on Jan 5th, 2021

Pamela Nadin-Mcintyre was introduced to the importance of innovation and its role in business at a young age.

As a daughter of a Windsor tool and die business owner, she remembers watching her dad brainstorm and execute countless ideas to drive business and stay competitive.

Decades later and three provinces away, she is the innovation lead — in addition to safety, technical safety, and risk management — for Canada’s largest independent crude oil and natural gas producer, Canadian Natural Resources Limited (Canadian Natural).

“My dad’s the one who really helped push me in this direction,” says Nadin- McIntyre BASc ’86.

In addition to ensuring the right systems are in place to maintain the safety of people across Canadian Natural’s operations, she leads dedicated teams that are focused on improving the company’s environmental performance through technology and innovation. And for someone who is passionate about the environment, it’s more than just a job.

— Published on Jan 5th, 2021

A team from the University of Windsor received top marks from the judges in the design review portion of the Canadian Satellite Design Challenge, in October in Quebec City.

The competition requires students to develop a satellite that can take a photo from space when commanded to do so by amateur radio operators around the world. It is intended to advance space education in Canada, inspiring students to pursue science and engineering educations and careers.

The satellites will undergo full launch and space environmental qualification testing, with the goal of launching the winning satellite into orbit.

In Quebec, teams conducted 2.5-hour presentations to a panel of industry experts.

— Published on Dec 20th, 2020

UWindsor Engineering students had the opportunity to participate in Manufacturing Day thanks to the Office of Experiential Learning.

On Oct. 4, Career Development and Experiential Learning organized a bus tour for 46 engineering students to tour manufacturing facilities and learn about their career options.

The annual event is coordinated locally by Workforce WindsorEssex.

Stephanie Dupley, career advisor in CDEL, said students were enthusiastic about their visits to Active Industrial Solutions and Valiant TMS.

— Published on Dec 20th, 2020

UWindsor Engineering alumnus Steve Ray has been inducted into UWindsor's Alumni Sports Hall of Fame for his outstanding performances in volleyball.

The 34th annual Alumni Sports Hall of Fame Induction Ceremony and Awards Presentation was held Oct. 6.

Following Sunday’s ceremonies, the Hall of Fame now boasts a distinguished membership of 135 inductees, 31 Sport Achievement recipients and 39 Team Achievement recipients.

— Published on Dec 20th, 2020