Several University of Windsor engineering students and alumni were honoured during a local celebration of the engineering profession.

Windsor’s Engineering Month Committee hosts an annual awards luncheon to “bring public awareness to the diversity and importance of the exciting fields of engineering and technology and invite prospective students to consider these professions,” said Tina Hawco, chair of the Engineering Month Committee.

The committee is comprised of engineers and technologists from local municipalities, consulting engineering firms, the University of Windsor, St. Clair College, professional associations and industry.

Priscilla Williams, a PhD candidate in the civil and environmental engineering department, Michael Cappucci, BASc ’11, and Aaron Blata, BASc ’14, were named the Top Three Under 30 during a ceremony April 13, 2018 at the Fogolar Furlan Club for demonstrating higher than average abilities to undertake engineering projects, outstanding work ethic and leadership early in their careers.

— Published on Jan 7th, 2021

A University of Windsor engineering professor will be featured in a Japanese science show for his investigation into the source of the infamous Windsor Hum.

A camera crew from Japan’s national public broadcaster NHK made a special trip to campus April 16 to interview and film Colin Novak, an associate professor in the mechanical, automotive and materials engineering department.

Production co-ordinator Takayo Nagasawa said the segment will run as part of an episode focused on the sound of the cosmos and people who make data from sound.

“We found out about the Windsor Hum and we couldn’t tell the story without interviewing Dr. Novak,” she said during a break from filming in the university’s Centre for Automotive Research and Education.

— Published on Jan 7th, 2021

A UWindsor Engineering graduate student represented the University of Windsor at a provincial Three Minute Thesis competition.

Liza-Anastasia Di-Cecco, a master's student in Materials Engineering, presented her 3D printing research at the Ontario 3MT® competition final on April 19, 2018 at York University.

Di-Cecco had three minutes and a single presentation slide to deliver her presentation titled "Move over plastic, we're 3D printing titanium."

"In my research, I’m studying the material properties of pure titanium made through a specific 3D printing process using plasma fabrication," Di-Cecco said. "I’m concentrating on looking at their strength, hardness, and durability, while also looking at what’s happening at the microscopic level to characterise these parts."

Di-Cecco said 3D printing is expanding our ability to make parts and more complex items such as custom prosthetics and orthotics and lighter and more fuel efficient cars.

"Even advanced rocket fuel nozzles that might someday get us to Mars; The possibilities of this research are endless," she added.

Three UWindsor Engineering graduate students made it to the final six in the University of Windsor's Three Minute Thesis competition where Di-Cecco took home a second-place prize of $500.

— Published on Jan 7th, 2021

Students from the course-based Master of Mechanical Engineering - Automotive program bring valuable skills with them into the workplace, says Gordon Leslie.

Corporate engineering manager at automotive parts supplier the Narmco Group, he was in attendance Wednesday at the Centre for Engineering Innovation for poster presentations by students on their experiences with co-operative education placements.

The Narmco Group was one of those co-op employers, and Leslie said engineering grads make a good fit for the industry.

“We used to promote toolmakers but we now we’re looking at hiring people with an engineering background,” he said. “Engineering students are learning to tackle problems.”

He was impressed with contributions by Triyambak Tripathy, who completed a co-op work term but has continued in a part-time job with the firm while he completes his degree.

— Published on Mar 23rd, 2018

A new weekend technology program offered by the University of Windsor is helping local companies meet market demands.

The Bachelor of Engineering Technology (BEng Tech) degree, originally designed to create a pathway from college to university, is now available on weekends for working professionals to expand their expertise in mechatronics, industrial automation, robotics, manufacturing and engineering operational functions.

“Companies heard about this and expressed a great deal of interest,” said Dr. Mehrdad Saif, UWindsor’s dean of engineering. “We thought why not do it on weekends for these types of students and put in place more courses around the theme of mechatronics and industrial automation. As an engineering school in Windsor, we have an obligation to meet the needs of the community and industry.”

— Published on Jan 7th, 2021

A project to design and build hydraulic robotic arms powered by syringes taught a class of engineering students about the challenges of the profession.

Teams demonstrated their creations for the third-year course “Manufacturing Process Design,” Thursday in the Centre for Engineering Innovation. Each project had to incorporate several joints and be able to grasp and lift an object, operated by rubber-piston needle syringes.

Designs incorporated wood and metal, dowels and glue, 3D-printed and molded plastics, employing fluids as different as oil and water to operate crab-like claws.

— Published on Dec 8th, 2017

M.Eng student Bhavesh Lakhankiya completed an internship at Diageo Canada Inc. in Amherstburg, Ont..

— Published on Jan 4th, 2018

Mechanical engineering students took a break from their books Friday to compete against their peers in a gravity car competition. More than 50 students took part in the friendly competition hosted for the first time by the university’s Master of Engineering Auto Student Advisory Council.

“This competition is an opportunity for students to showcase their design skills and their knowledge of fundamental engineering concepts such as aerodynamics,” said Tracy Beemer, program administrator for the MEng Automotive program.

— Published on Jan 7th, 2021

The head of the UWindsor Department of Mechanical, Automotive and Materials Engineering has been recognized by the Polish Academy of Sciences for his outstanding contributions towards advances in the knowledge of combustion process and technologies.

Andrzej Sobiesiak received the Dionizy Smoleński Medal September 5, during a joint meeting of the Polish Section of the Combustion Institute and XXIII International Symposium on Combustion Processes in Rynia near Warsaw, Poland after delivering a keynote lecture on “Internal Combustion Engines Fuelled with Solutions of Liquid and Gaseous Fuels.”

At the award ceremony, Dr. Sobiesiak was cited for his research on droplets combustion in microgravity, development and work on flameless combustion and ultra-low NOx burner, Homogeneous Charge Compression Ignition (HCCI) engines charged with fuels derived from biomass and unique split-cycle engine fuelled with natural gas.

— Published on Jan 7th, 2021

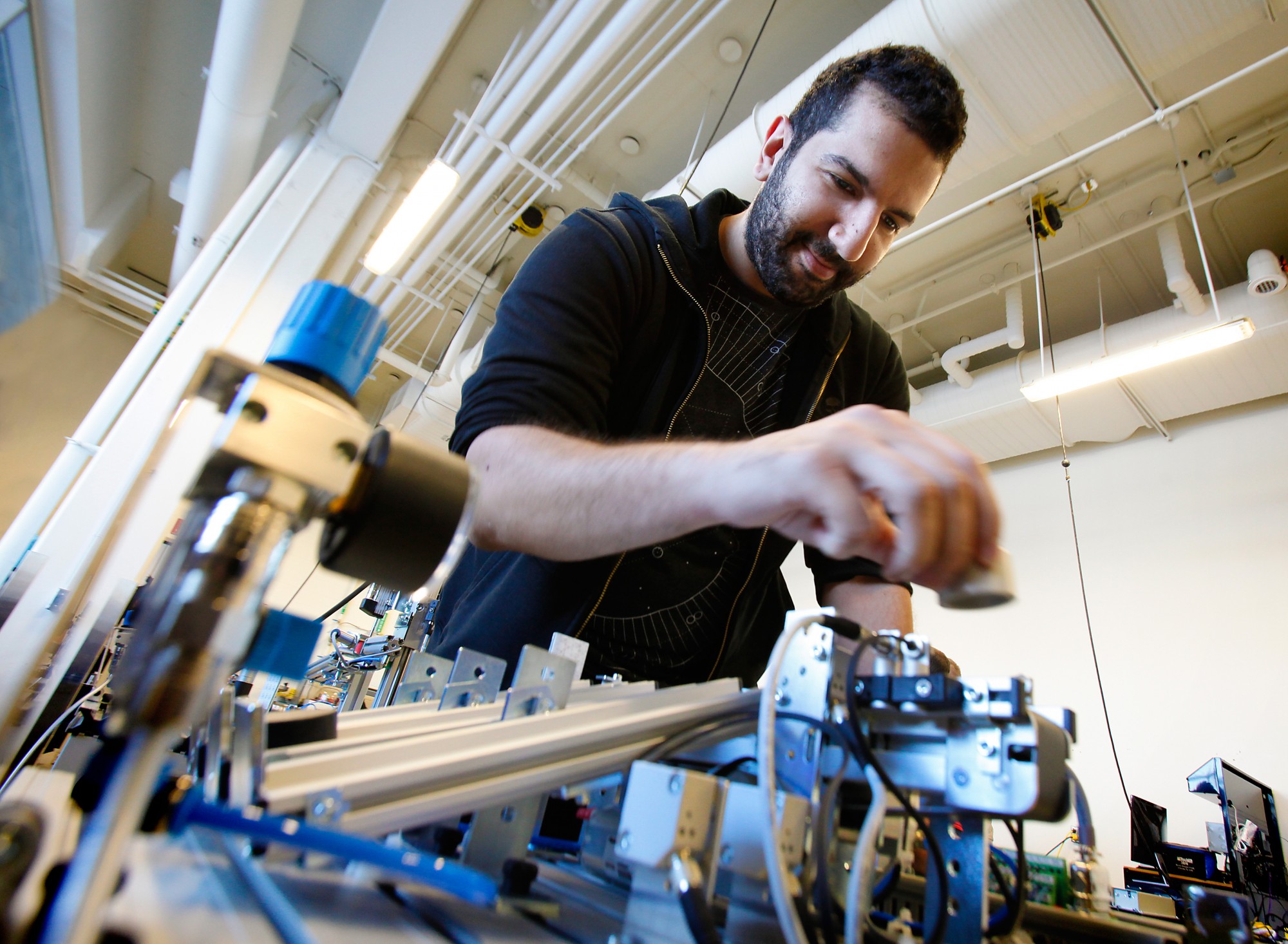

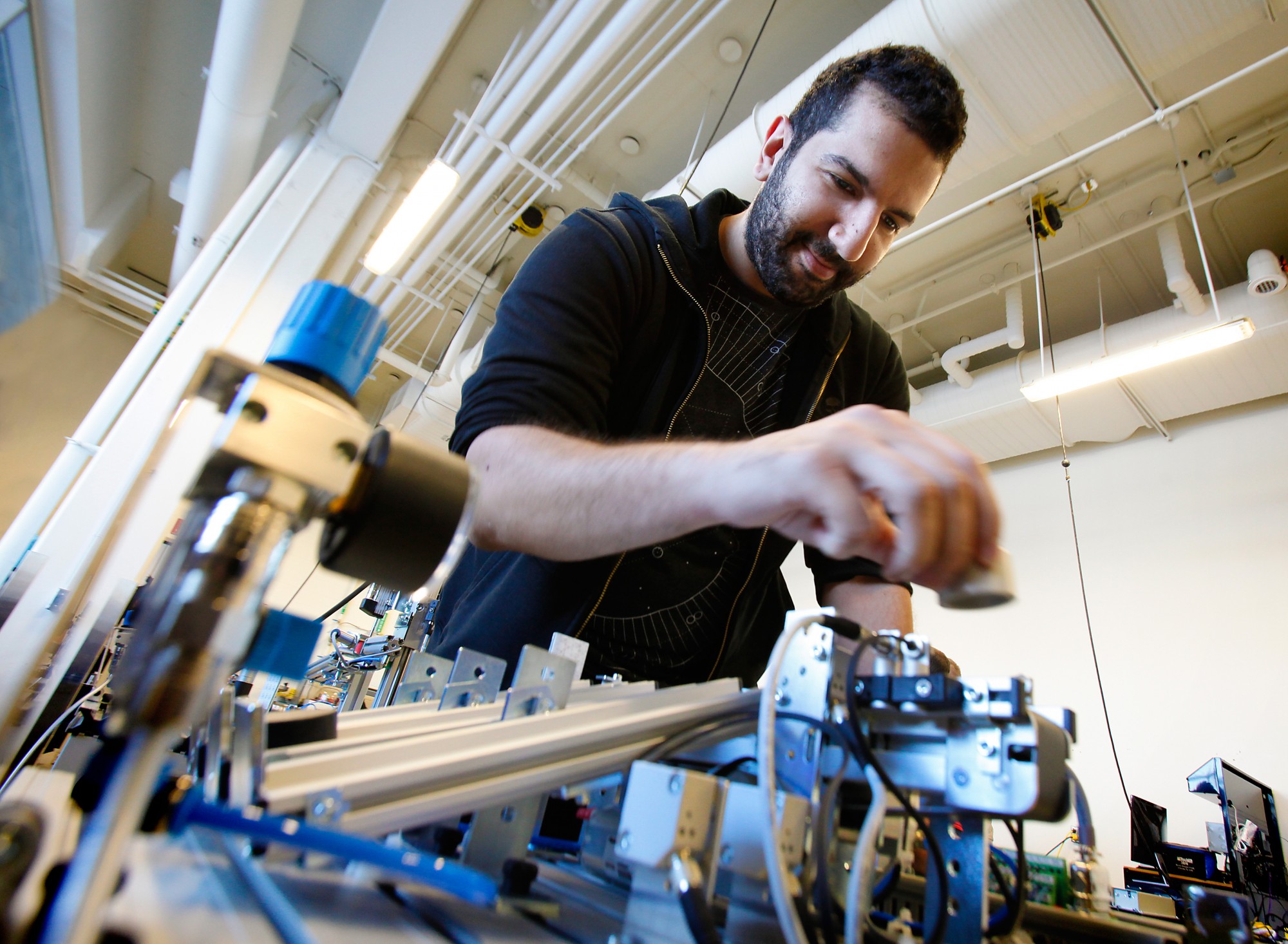

An injection of nearly $2 million in federal funds will aid University of Windsor researchers like Daniel Green, who is helping automakers incorporate lightweight sheet materials into their vehicles.

The automotive sector is turning to lightweight materials as an alternative to steel to improve fuel efficiency. However, lower-density metals tend to have limited formability, says Dr. Green, an associate professor who specializes in materials engineering.

“Innovative forming processes need to be developed and optimized for the production of automotive parts,” he said. “With high-speed forming, we can get 100 per cent more formability than we can with conventional stamping.”

Green is one of 14 UWindsor engineering professors who was awarded funding through the 2017 Discovery Grants Program — an annual competition run by the Natural Sciences and Engineering Research Council of Canada (NSERC) to advance research in Canadian universities.

— Published on Jan 7th, 2021