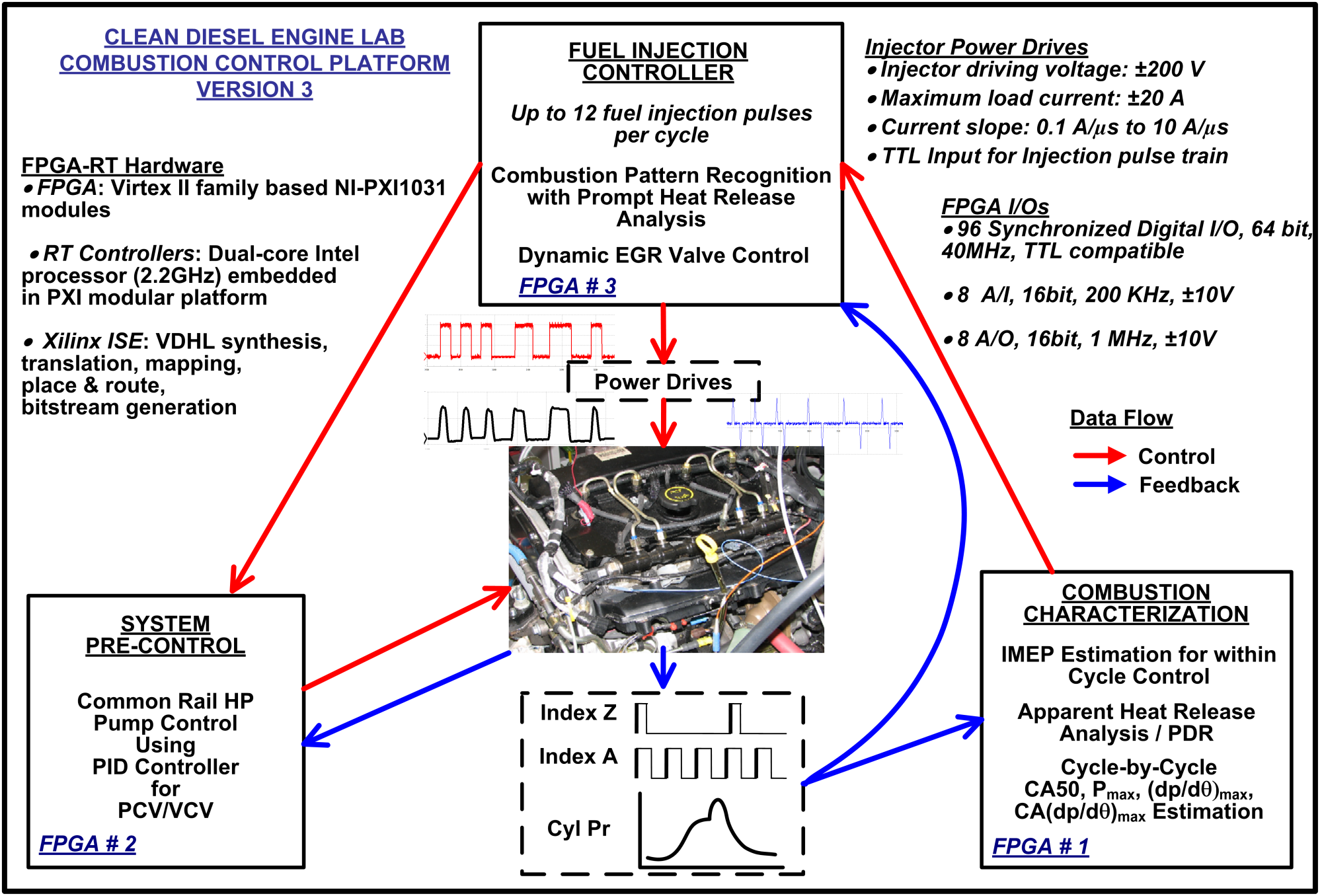

The fuel pressure and injection are independently controlled using Real-Time (RT) and FPGA ( NI hardware) controller system. Multiple FPGAs are synchronized through signals from encoder and the camshaft sensor. These control systems are used for combustion pattern recognition using online heat release analysis for adaptive combustion control and model predictive same-cycle or cycle-to-cycle combustion control. The control systems are also applied for biofuel engine research (ethanol, n-buthanol, DME, biodiesel) and dual fuel systems. A schematic layout of the control system is given below.

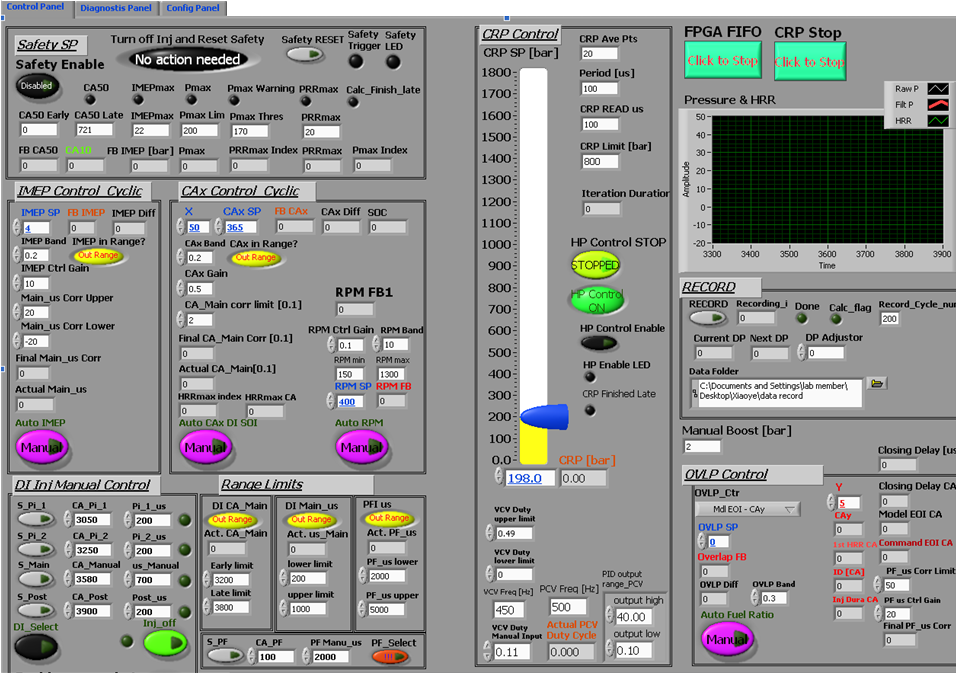

In-house developed LabVIEW programs are used for the control of fuel pressure and injection. Multiple fuel injection, port fuel injection, fuel injection timing and duration can all be customized using the developed program. A dynamic injection program with10 fuel injection events within one engine cycle can be viewed here (click for video). The main hardwares used in the fuel pressure and injection control systemhas are NI-RT-FPGA and in-house PCV/VCV control with H-bridge.