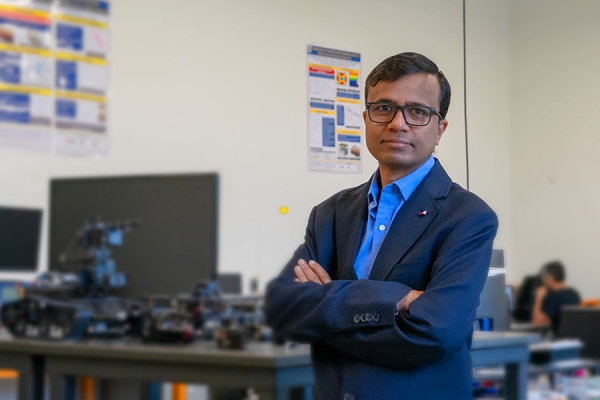

Acting associate dean of engineering for professional programs Darryl Danelon speaks with some new Master of Engineering students at a Sept. 3 orientation session.

Acting associate dean of engineering for professional programs Darryl Danelon speaks with some new Master of Engineering students at a Sept. 3 orientation session.

A new cohort of more than 200 Master of Engineering students has joined the campus community, and were welcomed with an orientation session on Tuesday, Sept. 3.

The students come from all over the world to acquire advanced skills, hands-on knowledge, and experience in industry, which prepares them for an engineering career in Canada.

The session included addresses by dean of engineering Bill Van Heyst, engineering’s wellness counselling staff and the International Student Centre, in addition to presentations on academic policies, course requirements, and faculty advising.

Darryl Danelon, acting associate dean for professional programs, says the event marked his favourite day so far in the position.