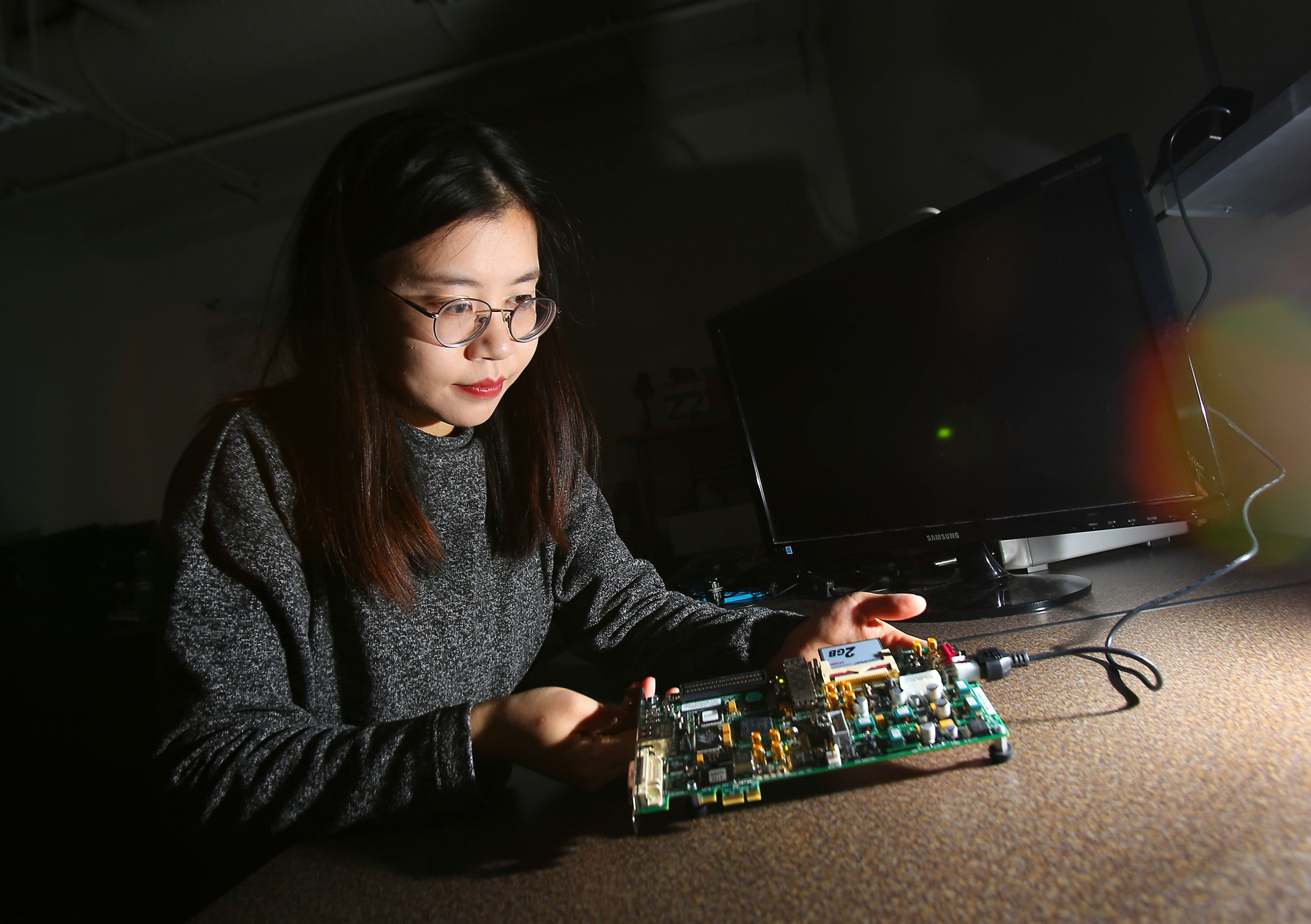

Meitong Pan, a master’s student who works with Dr. Mitra Mirhassani in the Analog and Mixed Signal Research Lab, examines an FPGA board used to implement complex digital computations.

Meitong Pan, a master’s student who works with Dr. Mitra Mirhassani in the Analog and Mixed Signal Research Lab, examines an FPGA board used to implement complex digital computations.

Driving cybersecurity evolution

Companies are well aware of the environmental benefits of electrifying vehicle fleets, but how much is known about the security of these systems?

A University of Windsor researcher aims to dig deeper through the investigation of cybersecurity issues that arise when using electric vehicle fleets with battery charging infrastructure.

“The environmental, geopolitical and financial advantages of electric vehicles are well-studied and addressed in many research publications. However, security of these systems is not given the full attention that it requires,” says Dr. Mitra Mirhassani, the project lead and associate professor who specializes in electrical engineering.

Amazon announced in fall 2019 the largest order of electric delivery vehicles ever, according to David Clark, Amazon’s senior vice president of operations. The world’s largest retailer purchased 100,000 electric delivery vans from Rivian, a Michigan-based start-up. While companies like Amazon are making the switch to electric fleets, municipalities are preparing with plans to add infrastructure to accommodate the surge in consumer and corporate investments in alternative fuels. The City of Windsor is looking to set up 11 dual-port electric vehicle (EV) charging stations across the municipality, according to a 2019 city council report.

The most common method of recharging electric vehicles is to use exchange or recharge stations. When the energy resources are converted to electrical systems, security issues come into play, Mirhassani says. The main components of a charging station include the main board, communication equipment that is connected to a central unit, radio-frequency identification (RFID) readers, and other electronic components such as circuit breakers and electrical measurement systems.

“This means that essentially a computer is placed on the street, with potential access to the smart grid that it is connected to. This creates the potential for weak security points that can provide a hacker with possible access to the primary network.”

Once they’re in the system, hackers have access to a plethora of information, which can lead to identity and financial theft and Denial of Service (DoS) attacks that can create a disruption in the electrical and power generation systems.

Mirhassani notes some of the weak points in EV charger systems include the physical access, which can be directly accessed through a panel, an open port or wirelessly through its communication lines. She also says the use of RFID access cards provide an easy and convenient way for vehicle operators to access charging stations.

“However, the security level of these cards is very low. An RFID card can be broken in a short time and hence is vulnerable to attacks.” Another weak point is “backdoors” used for maintenance and possible future system upgrades, which are often not protected, she adds.

The three-year project is funded in partnership with the WindsorEssex Economic Development Corporation as part of a FedDev Ontario $5 million investment in community economic development and diversification that supports the Windsor-Essex Region in transitioning from traditional automotive manufacturing to transformative automotive technologies.

Up to $640,000 has been allocated to the University of Windsor and Dr. Mirhassani’s work on cybersecurity and automotive technologies.

“This project will help further position Windsor-Essex as the automobility capital of Canada, by building on the automotive history, knowledge and experience of its past to emerge as a cybersecurity powerhouse in automotive technologies,” says Stephen MacKenzie, the president and CEO of WindsorEssex Economic Development Corporation.

Hydrogen: the fuel of the future

By Dr. Ofelia A. Jianu

There are 35.11 million vehicles registered in Canada out of which 12.55 million are registered in Ontario. Simultaneously, Canada’s population is 37.59 million out of which Ontario hosts 14.57 million people. This might all look good in terms of the economy; however, it is troubling when you consider that eight molecules of CO2 are released for every molecule of burned gasoline in an internal combustion engine. That translates to the average vehicle emitting approximately 4.6 metric tons of CO2 per year.

In 2005, automotive pollution was responsible for 20 per cent of the European Union’s CO2 emissions, roughly 60 per cent of which can be attributed to private automobiles. The EU legislation has set mandatory emission reduction targets for new cars in order to meet the targeted 95 grams of CO2 per kilometer by 2021, a significant drop from the 130 grams per km recorded in 2015. Still, this is not sufficient, and hydrogen may be a possible solution. Hydrogen can have a significant role in providing better environmental sustainability as it combusts clean in the presence of oxygen and the output is water. Sounds great, right? So, why are we not using hydrogen as fuel yet?

Well, although hydrogen is the most abundant element in the universe, filling stars and gas planets, it seldomly exists in its natural free state on Earth. Hydrogen strongly bonds to other elements, such as oxygen, to form water and vast amounts of energy are required to separate it. Additionally, hydrogen is only as clean as the method used to produce it. Currently the most common methods of hydrogen production are reforming fossil fuels in the presence of steam in processes such as steam methane reforming (SMR), coal gasification and partial oxidation of heavy oil.

The steam methane reforming method is the cheapest, but it releases carbon monoxide. You might have heard of “blue” hydrogen, which is produced via SMR and is not as bad for the environment as other methods of production, labeled “grey.” At the University of Windsor in the Alternative Fuels and Energy Laboratory (A-FuEL), we are striving to create “green” hydrogen: the purest, cleanest hydrogen produced using sustainable methods not based on fossil-fuels.

Some clean methods we are exploring are water electrolysis, thermochemical water decomposition, photochemical, photoelectrochemical and photobiological. Hydrogenics Inc. based in Mississauga, Ont. and Ballard, in Burnaby, B.C., are two internationally recognized manufacturers of water electrolyzers and fuel cells (electrolyzers operating in reverse). Other clean methods to produce green hydrogen are thermochemical cycles for water decomposition.

Thermochemical cycles split water into hydrogen and oxygen through a series of chemical reactions by recycling the constituents internally. The advantage is that they are capable of producing large amounts of hydrogen without releasing pollutants into our environment, while using waste heat from industrial emitters to drive the reactions. It would be no surprise if hydrogen production plants were erected next to nuclear power plants (waste heat at 450 ºC), cement plants (waste heat at 1,200 ºC) and foundries, to name a few.

This hydrogen research performed in A-FuEL is especially beneficial to Windsor considering Ontario’s and USA’s efforts to adopt hydrogen as a clean fuel. As a border city, Windsor is well positioned to become the “green” hydrogen generation hub, connecting the Greater Toronto Area and the United States. In A-FuEL, we produce the fuel of the future, so your wheels can keep on turning.