Humans have the widest range of physical and mental skill sets and dexterity of any creature.

We learn… We adapt… We develop…

But we are NOT general purpose devices.

Contemporary manufacturing systems are complex, and highly interactive.

Physical aspects relate to dexterity and skill development.

Cognitive aspects relate to information gathering, analysis and decision making.

Performance changes with time.

Understanding and modelling system performance is challenging: How can we do this?

Using a systems approach to highlight areas of concern & provide insights.

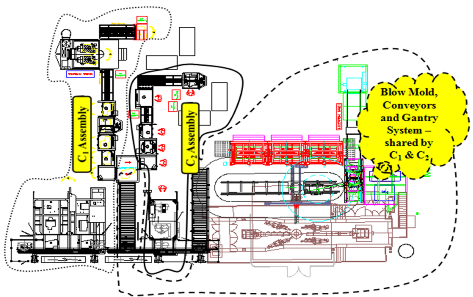

Here is a complex mfg system

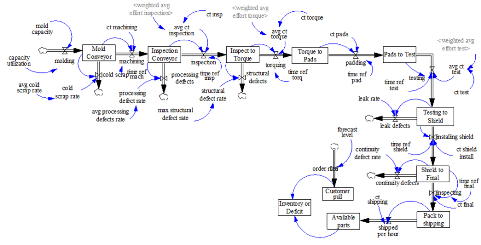

Let's model it using a Systems Dynamics approach, and include a skills-rules-knowledge factor

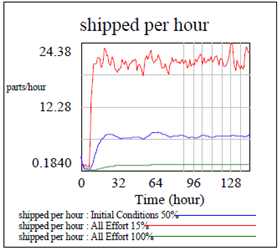

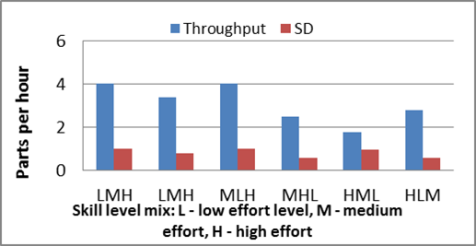

And see the results on throughput for peopel with different skill levels - OK no new news if something takes alot of effort you do not get a high amount of results. But lets mix it up - let us consider three operators that each have a different skill level, and change their placement in the system.

This is interesting - same people, different placement, different throughput. Maybe this is why ramp up results are so unpredictable.