Upstairs at the North American International Auto Show is this year’s array of new cars being unveiled by automakers, but the lower level was where the wizardry behind them begins.

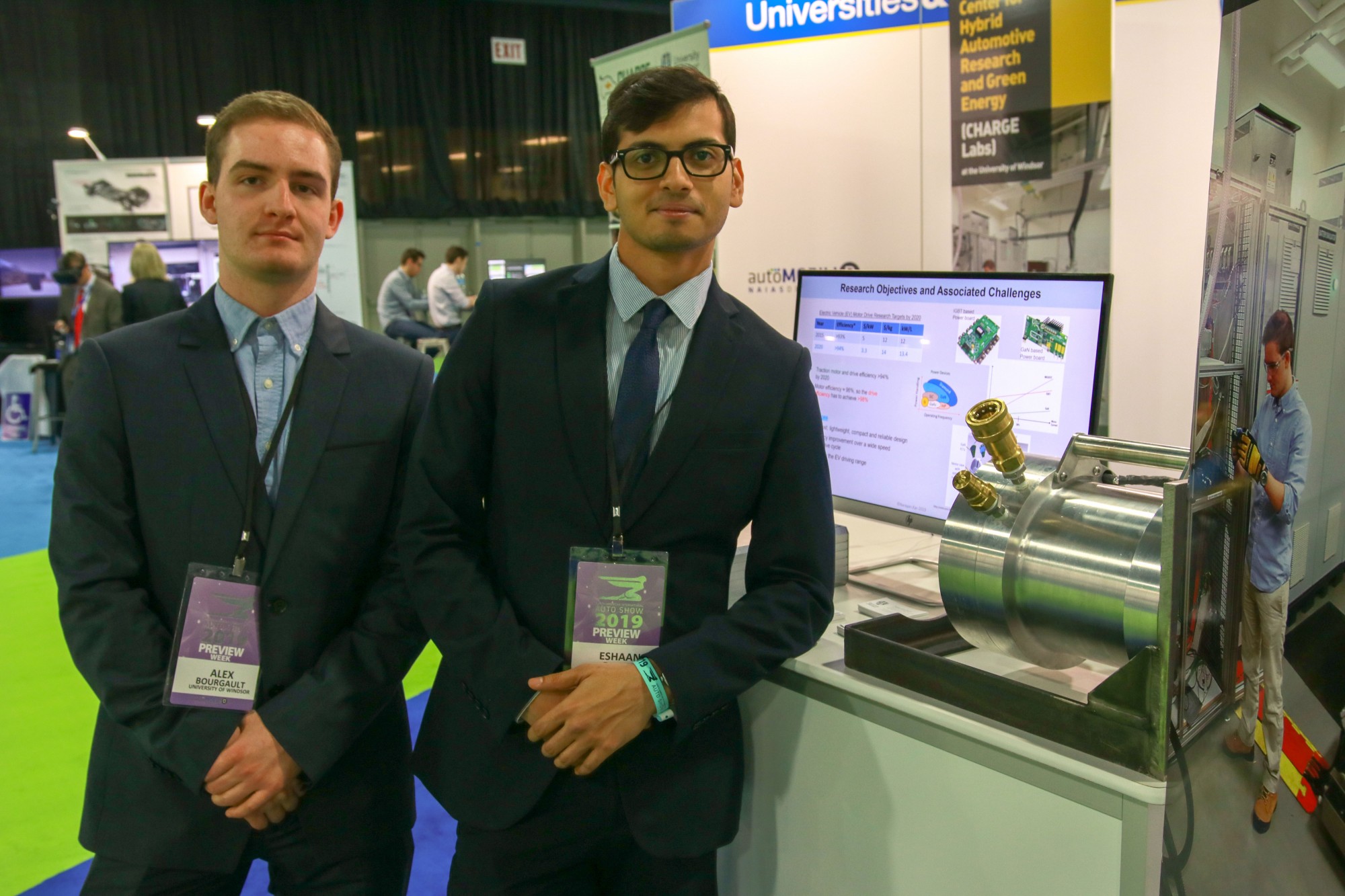

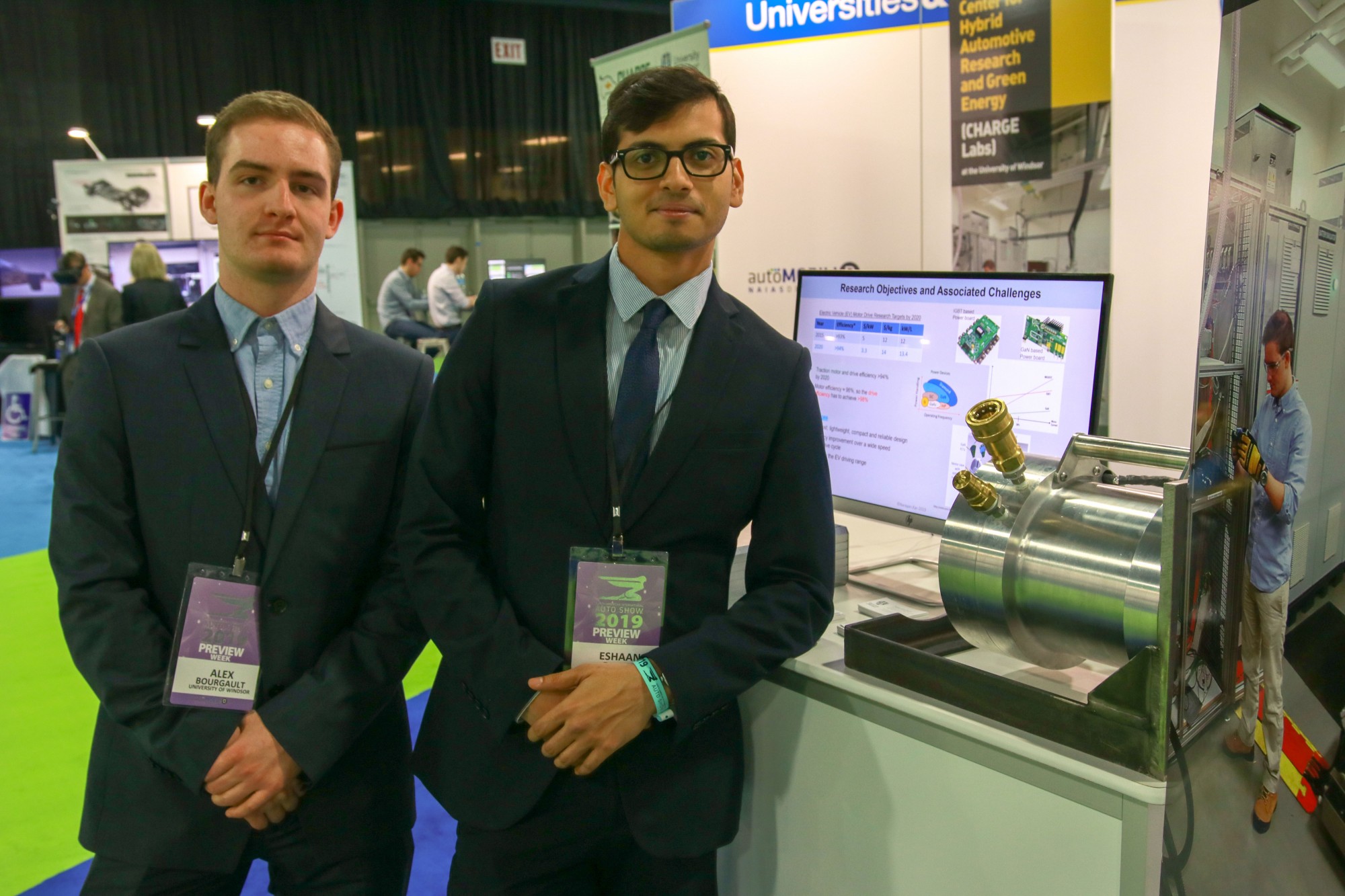

Researchers from UWindsor Engineering’s Centre for Hybrid Automotive Research and Green Energy — CHARGE, for short — were among the exhibitors on the lower level of Cobo Center, displaying a prototype of an electric motor created in collaboration with Ford Motor Company of Canada.

CHARGE Labs researchers also brought along a controller that runs an electric motor, and information on the independent, third-party testing they can provide manufacturers developing their own electric vehicles.

“We are here to showcase the contributions we are making as a university with this lab,” said Narayan Kar, director of CHARGE Labs and a professor with expertise in electrified transportation systems. “We are creating knowledge and experts for the future…. That’s what we’d like to demonstrate to the outside world.”

— Published on Dec 21st, 2020

UWindsor’s Hyperloop team is one of 52 teams worldwide to advance in a competition that encourages innovations in high-speed transportation.

The team formed in 2017 and hasn’t stopped working towards its goal of creating an electrically powered linear induction motor to propel a levitating pod through a sealed tube at speeds over 500 km/h. The group’s initial design work has helped them advance in SpaceX’s Hyperloop Pod Competition.

“We’re very dedicated to this,” says Stefan Sing, the team lead and founder who’s in his third year of mechanical engineering. “We’ve invested heavily in the linear induction motor and haven’t stopped making revisions. The team has been doing a stellar job.”

The team of 25 meets five times a week and ranges from undergraduate to graduate students studying mechanical, electrical and industrial engineering, and computer science.

— Published on Dec 21st, 2020

What if family doctors had access to low-cost, handheld scanners or biosensors that could detect cancer at an early stage? What if they could monitor a patient’s heart activity through a wearable device and detect early signs of cardiovascular disease? How about a sensor that could prevent intoxicated drivers from operating vehicles or a navigation system that could aid the visually impaired indoors?

Researchers at the University of Windsor hope to advance these technologies and more in Windsor’s first state-of-the-art microfabrication facility. The high-tech clean room will be specially designed to facilitate multidisciplinary micro- and nano-scale research by controlling air pollutant levels, pressurization, temperature and humidity. It’s slated to open in 2019 in the Ed Lumley Centre for Engineering Innovation.

“This fabrication facility will provide us with an ideal incubator for academia and industry to foster collaborative research and commercialization of advanced sensors, thus increasing our leadership in the emerging area of the micro nano sensor industry — an area which is rapidly growing,” says Dr. Jalal Ahamed, an assistant mechanical engineering professor who designs and fabricates micro- and nano-systems for a variety of applications, including healthcare, automotive, aerospace and manufacturing.

— Published on Jan 5th, 2021

The exciting part of working on a project redesigning the intersection of California Avenue and Wyandotte Street is the possibility of seeing it implemented, says Emma Teskey.

A fourth-year civil engineering student, she was part of a group that suggested several changes to the pavement and traffic signalling systems that would make the crossing safer for pedestrians and smoother for vehicles.

It was one of more than 60 projects displayed by graduating engineering students during Capstone Design Demonstration Day, Friday in the Centre for Engineering Innovation.

Teskey and her teammates — Abigayle Diemer, Kailee Dickson, Curtis Lanoue, and Sarah Zaarour — suggested altering the traffic signals so that cars and trucks are stopped in all directions while pedestrians cross, a system known as the “pedestrian scramble.” They also proposed adding wide white stripes to the crosswalk pavement and relocating a transit stop so buses do not block the intersection.

— Published on Jan 7th, 2021