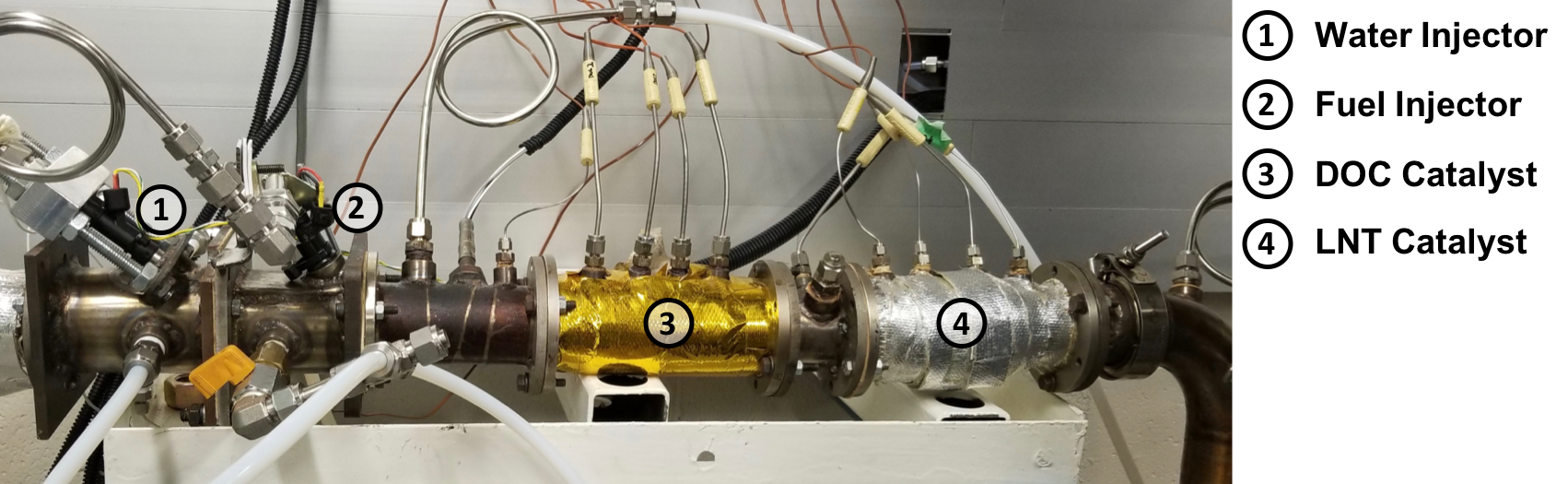

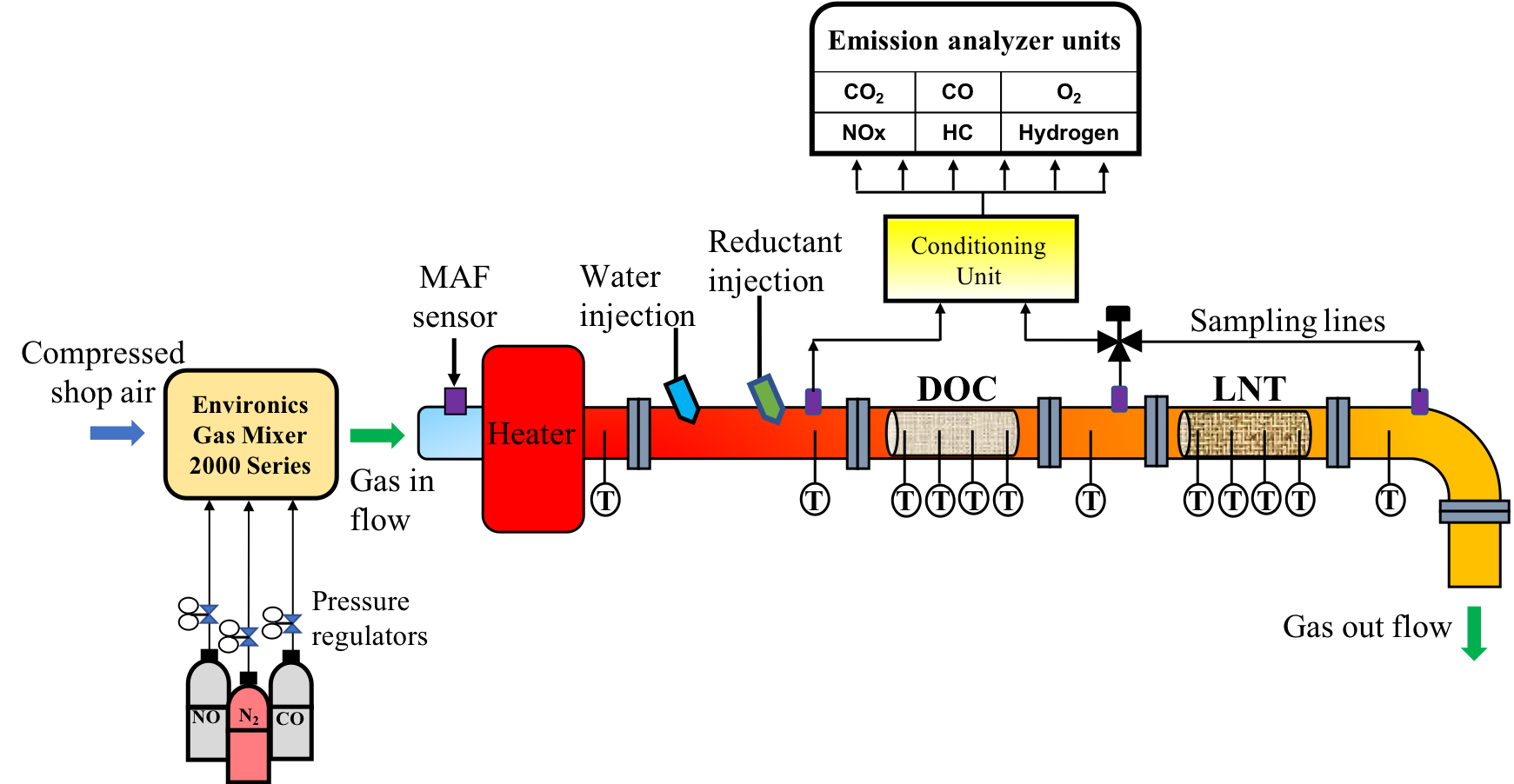

The after-treatment test bench allows flexible control of the concentration of different gases and flow rates as per test requirements. The modular research bench can be adapted for different research for diesel and gasoline after-treatment strategies such as DOC-LNT-SCR or three-way catalytic converter. An Environics multi-component gas mixer is used to create gas mixtures at controlled compositions to simulate engine exhaust conditions. The heated bench is equipped with a heater and an insulated supply line to create a high-temperature environment comparable to engine-out conditions. An after-treatment injection system is fitted in the test bench for water and reductant injection. The injection duration and timing is controlled with a LabVIEW program on an RT controller. Multiple gas analyzers are used for gas speciation and analyses. Comprehensive analysis of different species formed during catalytic reactions is performed by using California Analytical Instruments and MKS 2030-HS Fourier transform infrared (FTIR) spectrometer.

After-treatment Research Bench

An Example of After-treatment Bench Setup

Exhaust After-treatment Research Capabilities

|

|