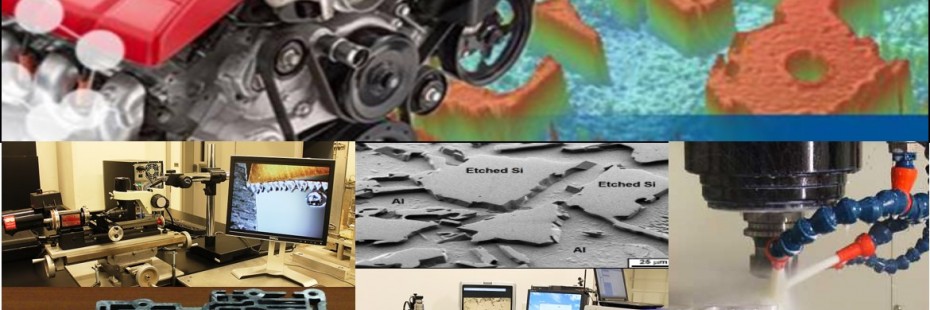

- Consists of integrated laboratories with a suite of tribometers: hot forming tribometer, in-situ observation tribometer, reciprocating, block-on-ring, pin-on-disc tribometers and instrumented CNC for tool coating assessment. Thin-film fabrication facilities: PVD sputtering and electrodeposition systems. Surface characterization facilities: digital and electron micro-scopes, surface profiling systems and micro-Raman spectrometer.

- Research programs are aimed at developing wear mechanisms maps, minimization of friction in auto-motive engines using tribological coatings on light-weight alloys, metal-matrix composites and nano-structured materials. Novel material characterization techniques are developed for identifying the physical mechanisms occurring when lightweight alloys contact another moving hard surface, such as a piston ring or a cutting tool.

- Machining research programs are focused on developing a cost-effective technology for environmentally sustainable machining of automotive and aerospace components. Near dry-machining techniques reduces the need for large amounts of metal cutting fluid and coolants extending tool life and increasing product quality, and predictive computational and numerical models to design wear resistant tool materials.

- Develops new surface engineering techniques using carbon-based materials, diamond-like carbon, graphene for die/tool surface friction reduction.

- Develops new technologies to help industrial designers select and design systems or components that are resistant to wear, yet easy to machine and form.

To get involved with the Tribology of Materials Research Centre

Contact: Dr. Ahmet Alpas

Department of Mechanical, Automotive and Materials Engineering

519-253-3000, Ext. 2603

tribology@uwindsor.ca

Visit uwindsor.ca/tribology for more information.