New Laboratories in CEI

Metallography Laboratory

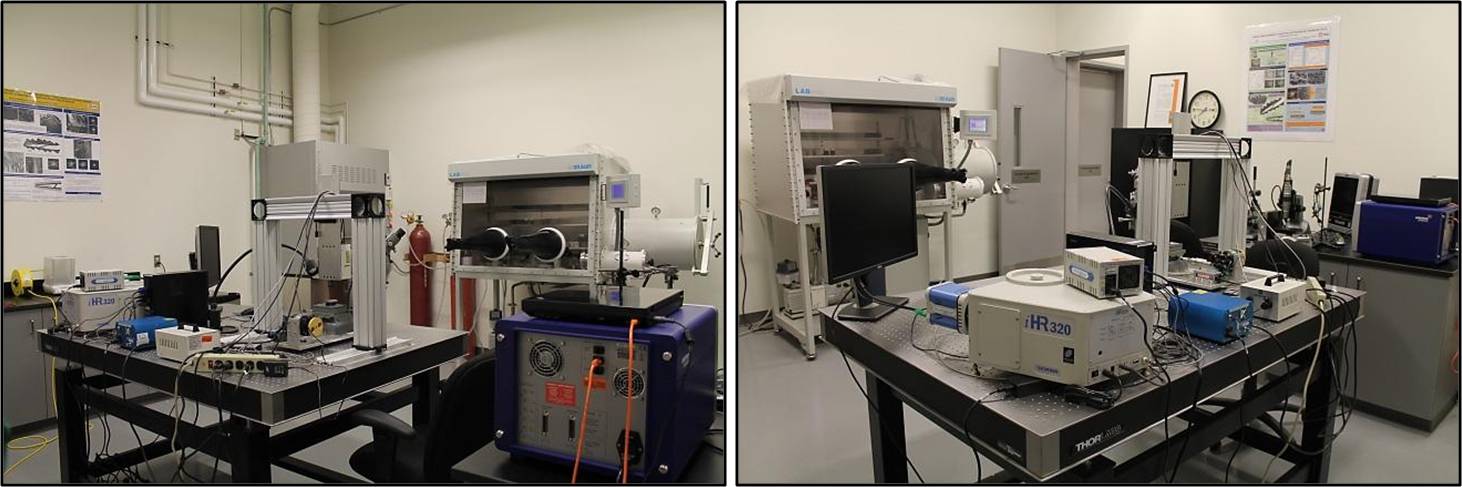

Tribology and Surface Characterization Laboratory

Surface Engineering Laboratory

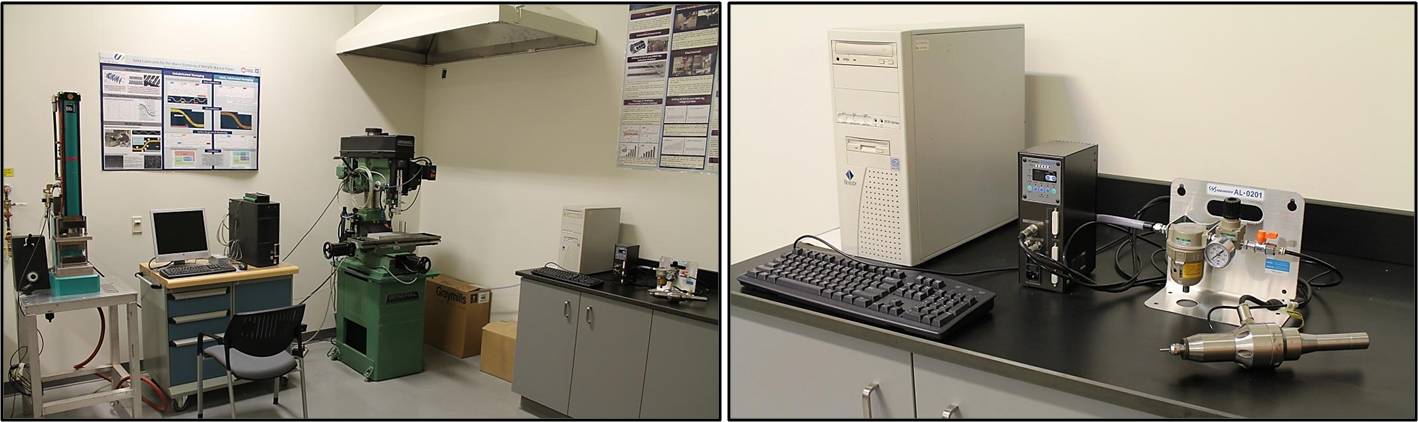

Tribology of Machining and Metal Forming Laboratory

Equipment

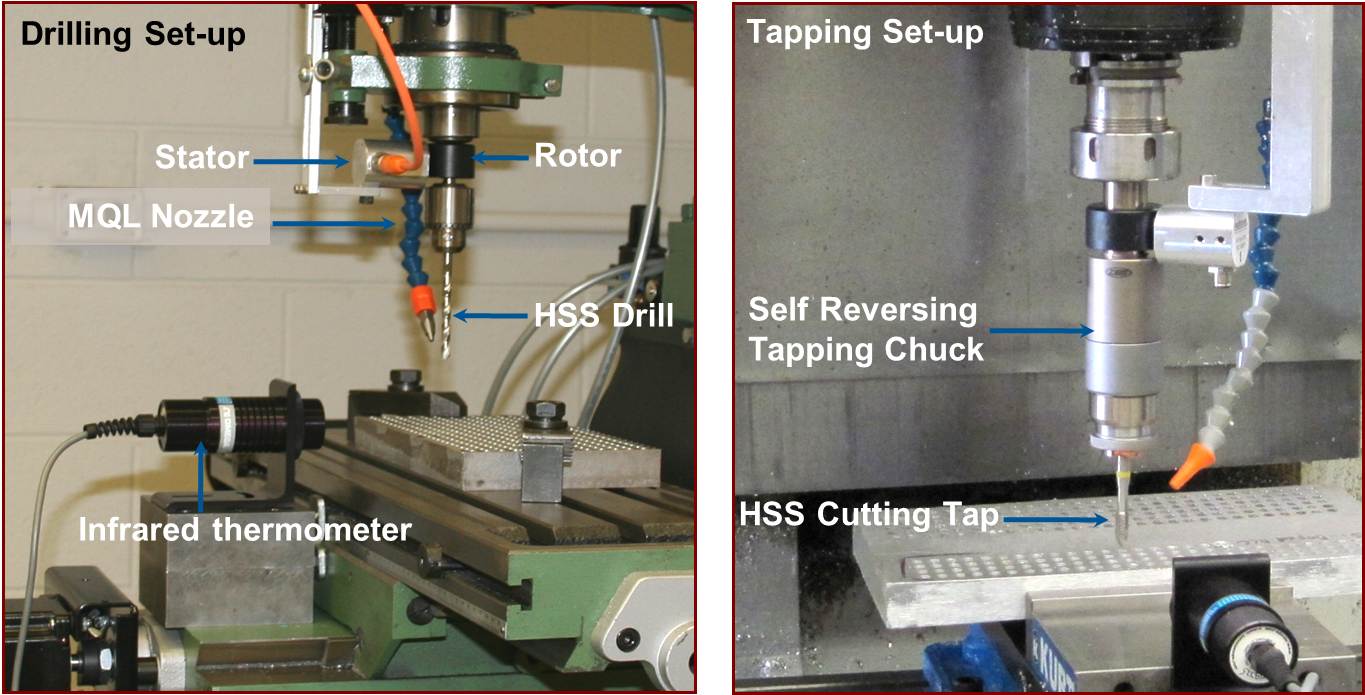

CNC Drill Press

This instrument is a computer numerically controlled (CNC) drill press with a maximum rotational speed of 60,000 rpm. The CNC unit is controlled by a user friendly Master software (G-code).

The drilling station is equipped with an external minimum quantity lubricating (MQL) system. The MQL system has a droplet size of as low as 0.5 µm. A non-contact magneto-static torque-thrust force sensor is mounted on the chuck located between the drill tip and the drill motor to measure the torque and thrust force generated during drilling.

BOC Edwards Auto 306 Sputtering System

The equipment includes a standard turbo pump, high voltage d.c. power supply for the magnetrons, r.f. power supply, heaters and two magnetrons. The system is able to deposit thin films of metallic and non-metallic materials on a variety of materials.

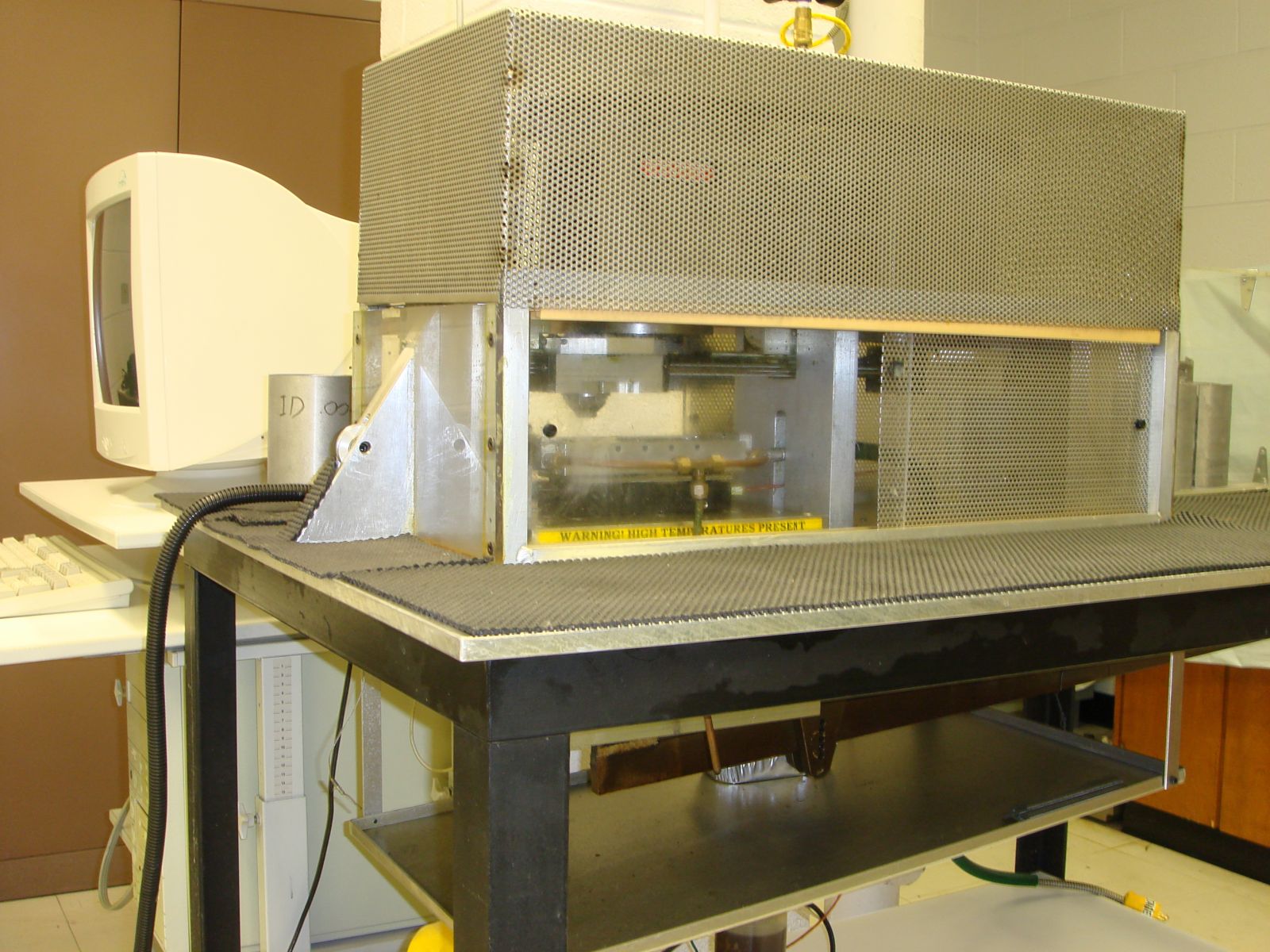

Hot Forming Tribometer

This tribometer has been fabricated to study the mechanical and tribological aspects of superplastic forming of metallic sheets. The machine is able to measure the coefficient of friction and mechanical properties of stretching metallic strips during sliding against tool materials at elevated temperatures.

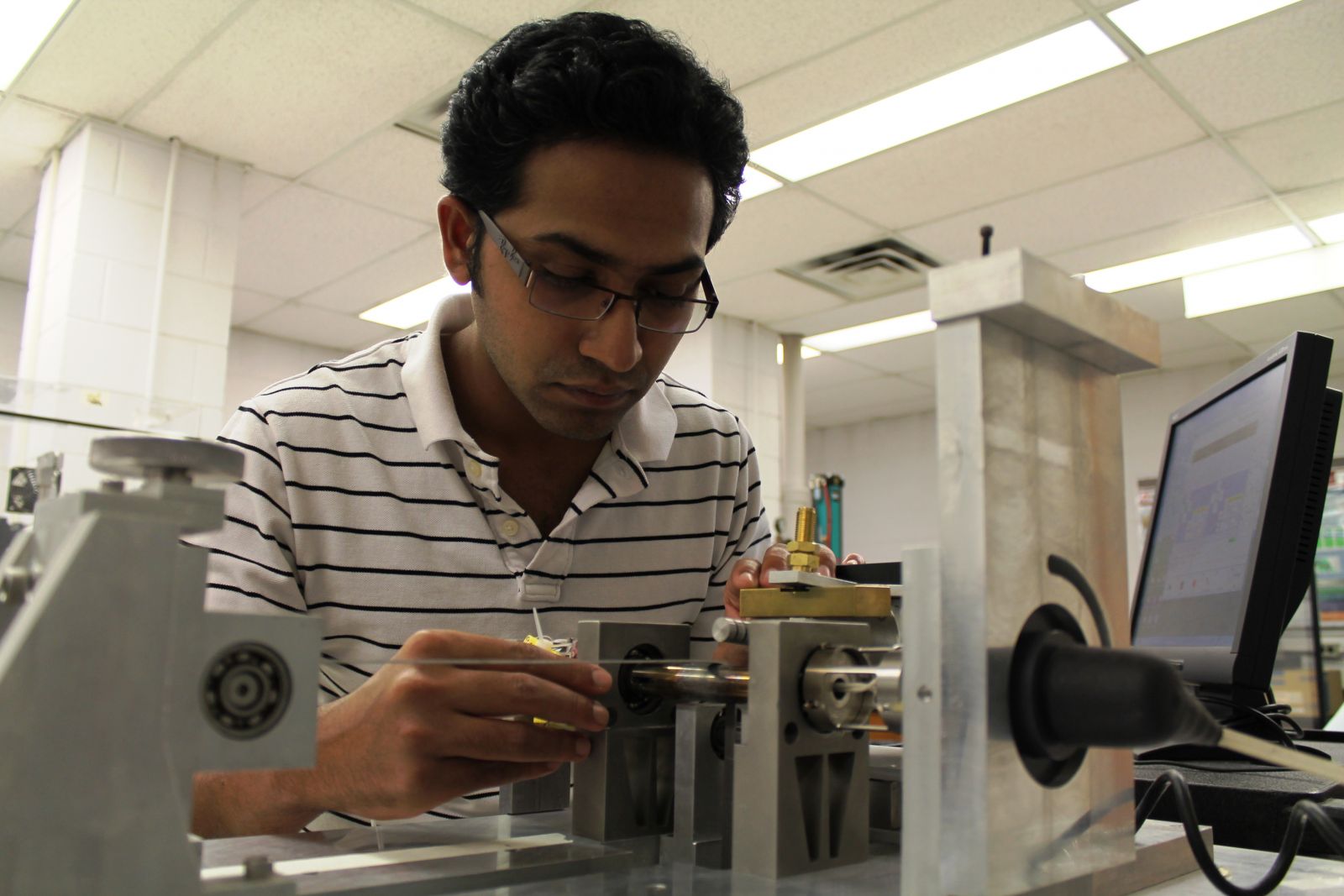

In-Situ Observation Tribometer

This instrument has been fabricated to study the in situ tribological interactions between contact surfaces. The instrument is able to measure the coefficient of friction between the sliding contact surfaces at temperatures up to 450 C and take video clips of the interaction of the contact surfaces through a transparent counterface. It can be used to evaluate the adhesion between materials as well.

Reciprocating Tribometer (Engine simulator)

Equiped with friction and temperature measuring and recording systems, this instrument can operate at temperatures up to 250 deg. C and velocities up to 3000 rpm under lubricated or dry conditions with a long stroke of 15 cm.

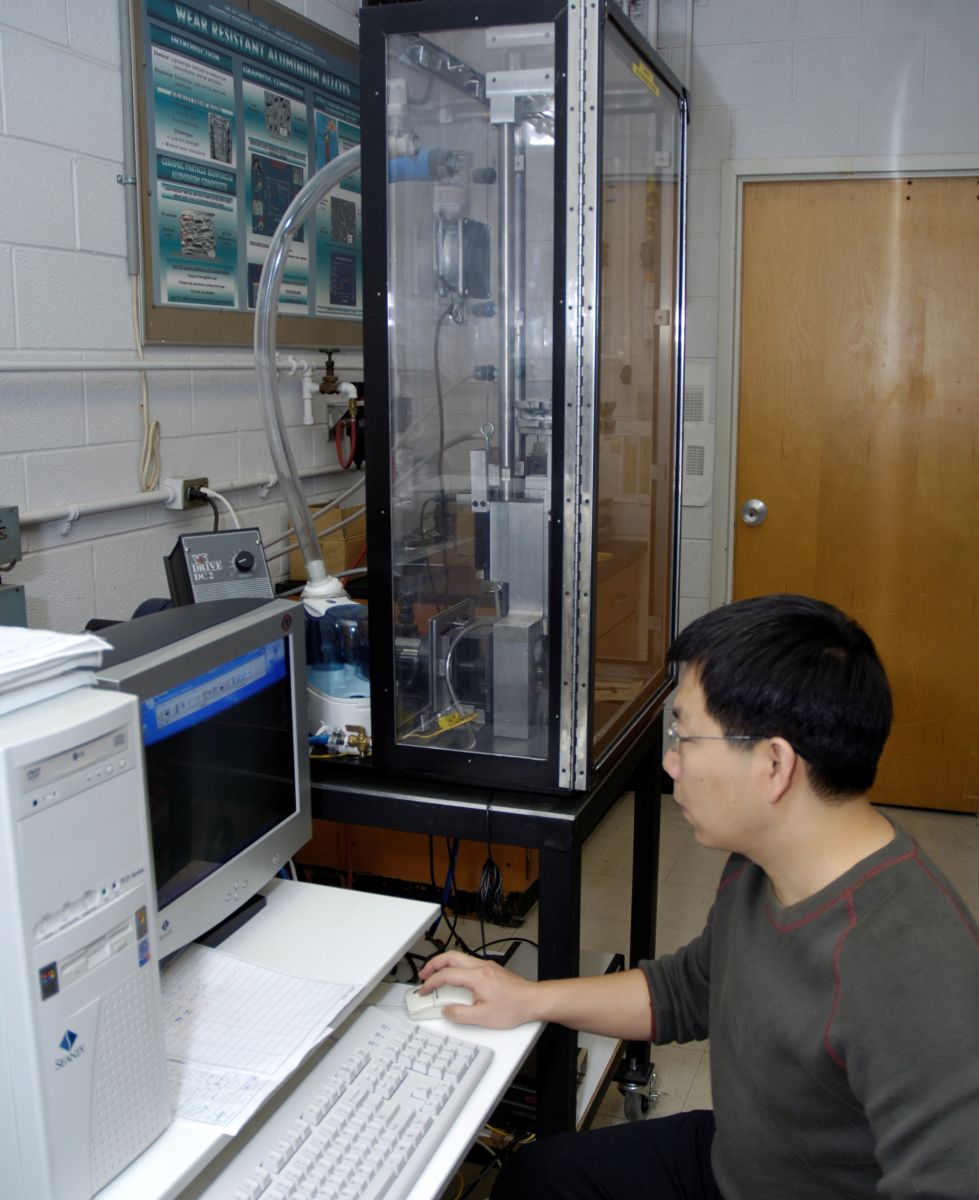

Pin-on-Disc Tribometer with Environmental Chamber

This tribometer is equiped with an environmental chamber for controlling humidity, and can measure and record frictional forces and surface temperature at different loads and sliding speeds using LabView operating system.

Pin-on-Disc Tribometer

Equiped with a self-adjusting specimen stage, this tribometer is capable of measuring frictional forces as well as surface temperature.

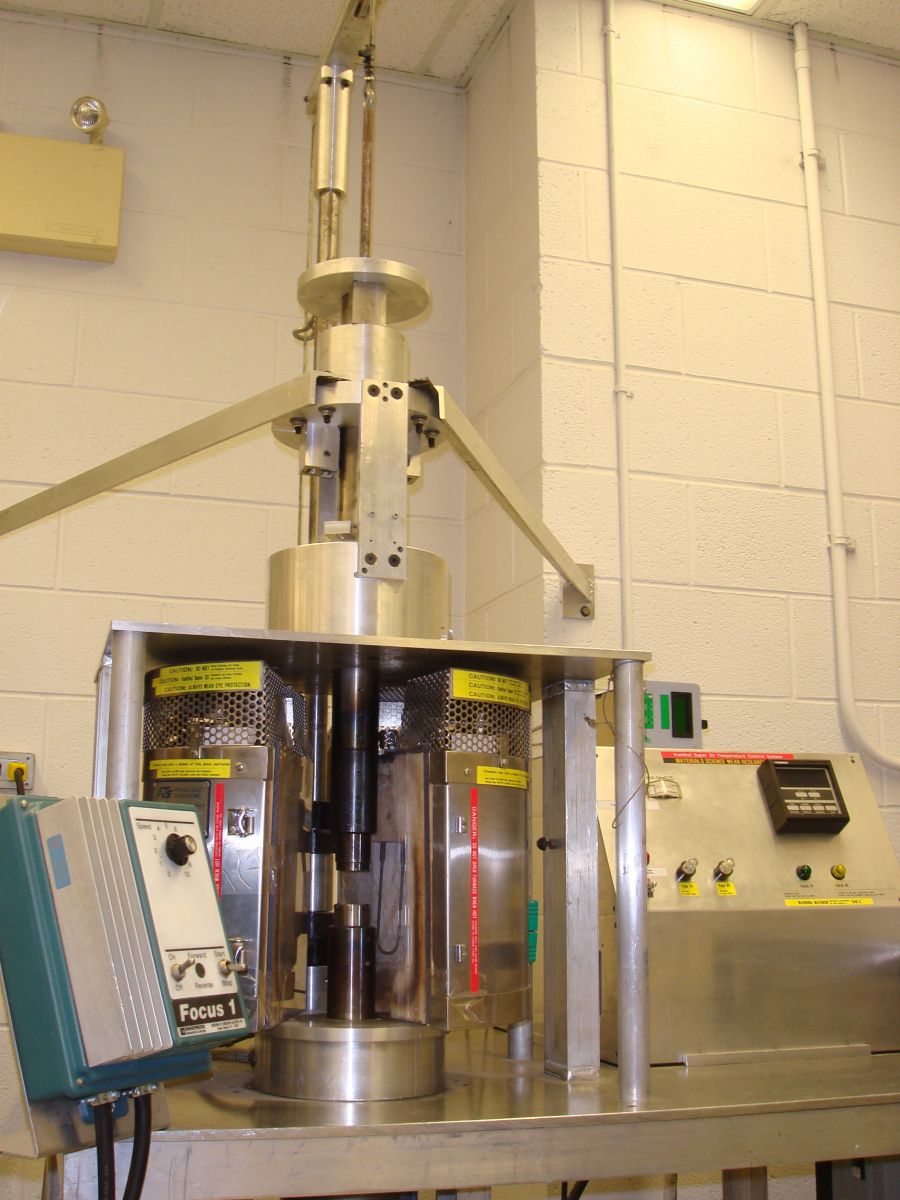

High Temperature Pin-on-Disc Tribometer (High Load)

This tribometer can operate at elevated temperatures up to 900 deg. C under 10-500 N normal loads. It is capable of measuring frictional forces as well as surface temperature.

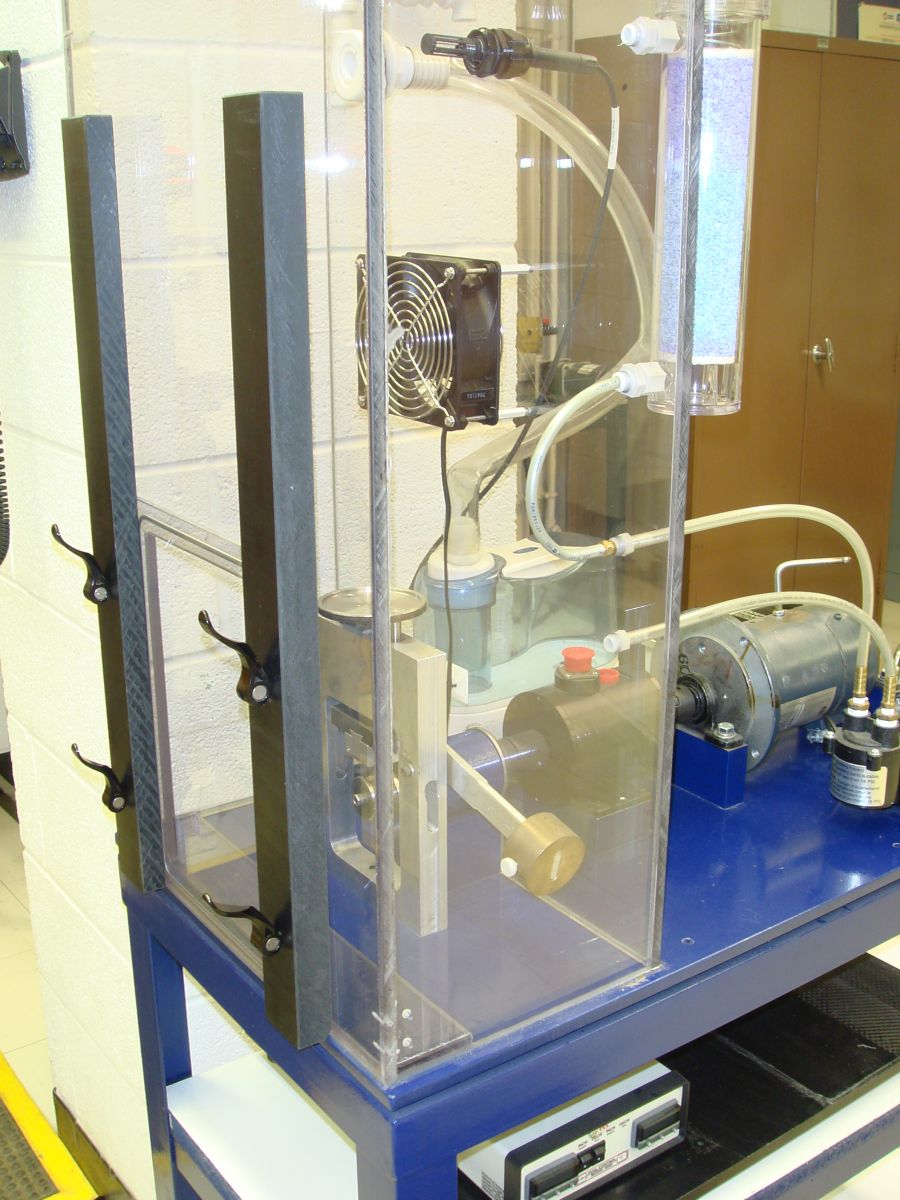

Block-on-Ring Tribometer with Environmental Chamber (Low Load and Speed)

Designed and constructed in the NSERC/ GM IRC labs, this tribometer operates under 0.1-40 N loads at 0.1-2.0 m/s sliding speeds under controlled atmosphere.

Block-on-Ring Tribometer with Environmental Chamber (High Load and Speed)

Designed and constructed in the NSERC/ GM IRC labs, this tribometer operates under 1-400 N loads at 0.5-3.0 m/s sliding speeds under controlled atmosphere.

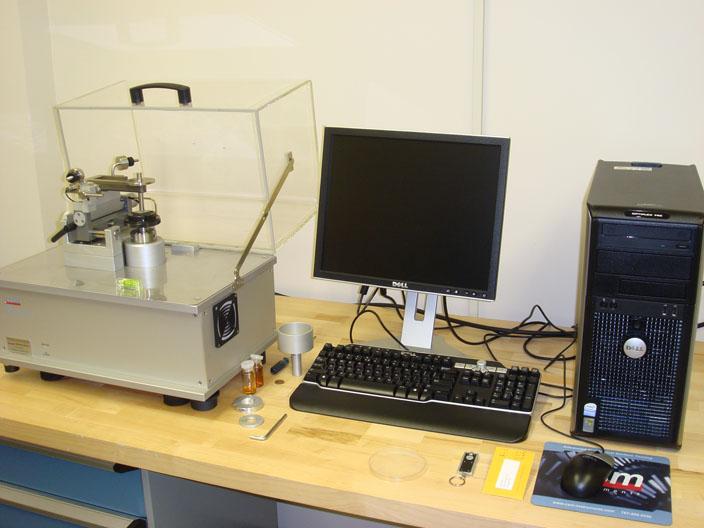

CSM Standard Pin-on-Disc Tribometer

The control of friction and wear in moving machine parts is a critical issue facing the manufacturing industry. The CSM standard tribometer is a pin-on-disc instrument that is used for precise friction and wear measurements in dry or lubricated conditions at room temperature.

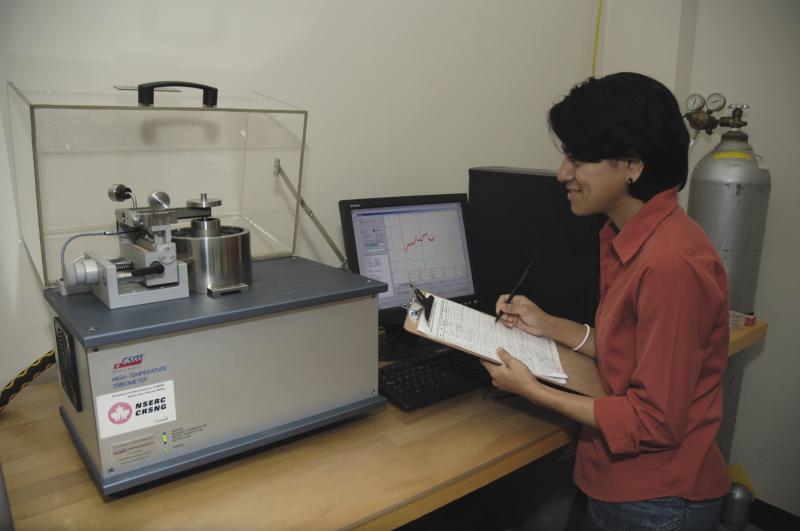

CSM High Temperature Pin-on-Disc Tribometer

The analysis of friction and wear properties of materials at elevated temperatures is becoming increasingly important, especially for the development and quality control of combustion engines and power plants. The CSM HTT is a powerful high-temperature pin-on-disc tribometer which can accurately simulate in-service conditions. It is capable of precisely measuring friction and wear properties at elevated temperatures up to 1000 deg. C, and performing tribological tests in liquids (within their thermal stability range). Testing conforms to DIN 50324, ASTM G99 and ASTM G133.

Keyence Digital Microscope VHX-600

Digital microscope with the fastest real-time depth composition and 3D functions. Includes integrated 54 Megapixel 3CCD pen-sized camera, 15-inch high-definition LCD monitor and more.

Veeco Surface Profiling System NT-1100

Fast and repeatable, the Wyko NT1100 provides high resolution 3D surface measurement, from sub-nanometer roughness to millimeter-high steps. The small-footprint NT1100 offers all the advantages of industry-standard Wyko optical profiling, including the full Vision 32 analytical software package. Advanced optics ensure sub-nanometer vertical resolution at all magnifications. The Data Stitching option adds a motorized stage for high resolution measurements over a larger field of view. The NT1100 enables accurate, cost-effective metrology for R&D and production of MEMS, thick films, optics, ceramics, and advanced materials.