Researchers to apply AI to improve human element in manufacturing

Two UWindsor engineering researchers have received more than $715,000 in federal funding to bring cutting-edge artificial intelligence to the manufacturing floor.

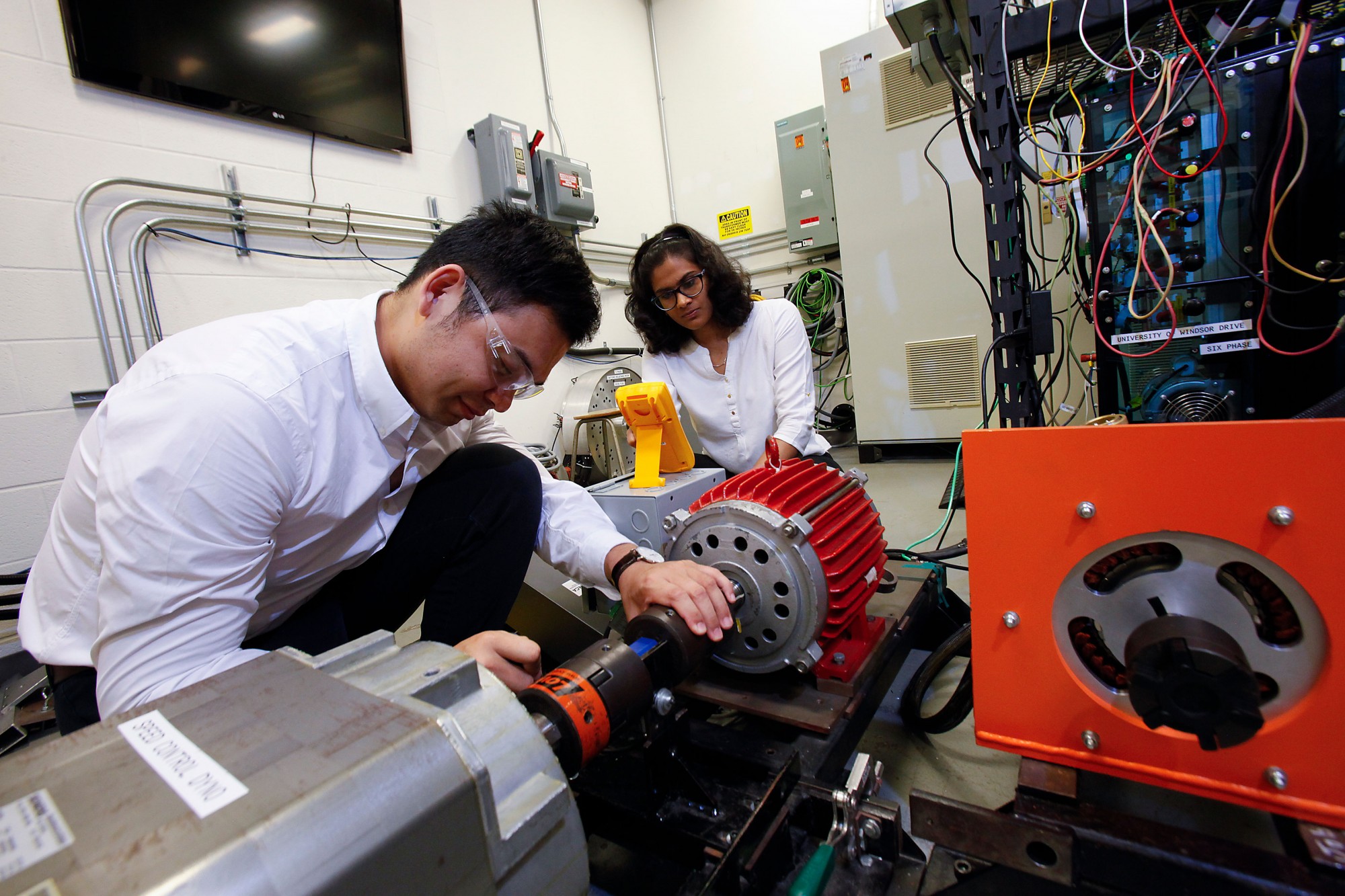

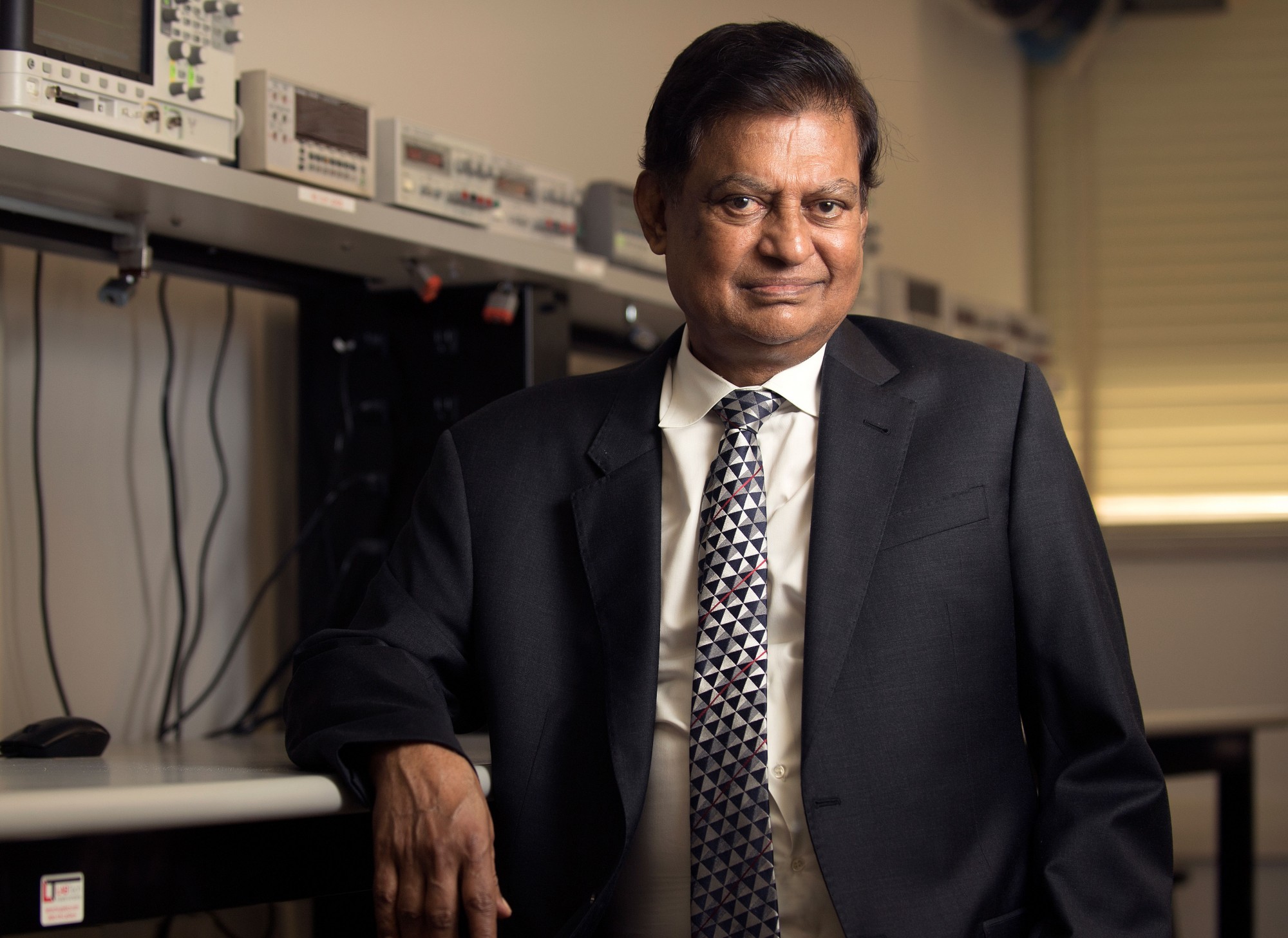

Professors Jonathan Wu and Afshin Rahimi say they can mitigate human error and maximize productivity in manufacturing plants through advanced computer vision.

“Human errors were the major driver behind $22.1 billion in vehicle recalls in 2016,” says Dr. Wu, a former Canada Research Chair in Automotive Sensor and Information Systems.

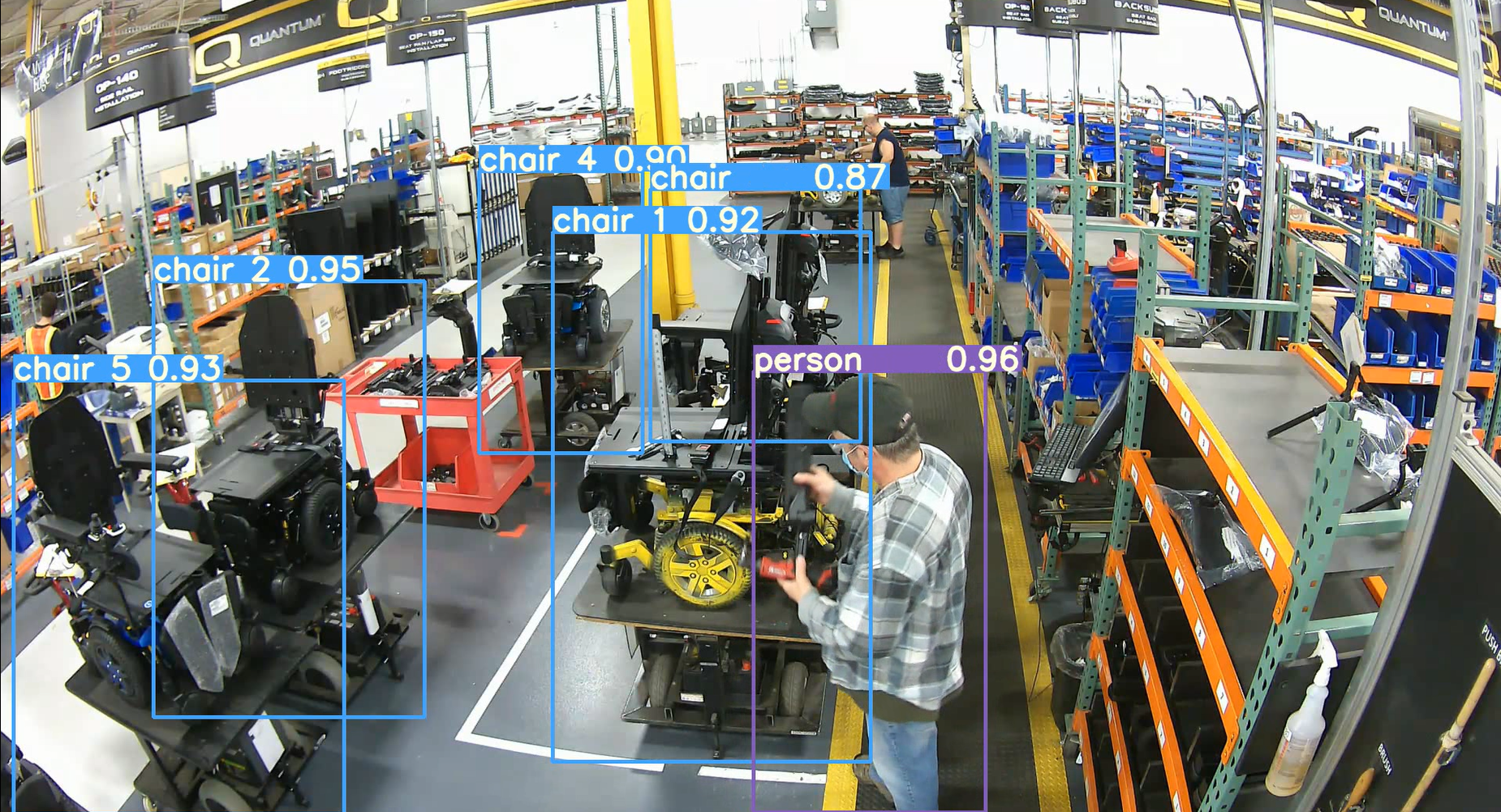

He and Dr. Rahimi aim to create a smart production assistant that will help manufacturing plant operators gain unprecedented visibility into their manual production operations, allowing them to optimize their worker efficiency while maximizing productivity. They will achieve this by automating data generation using computer vision, converting raw data into useable information, visualizing information using common business intelligence methodologies and prediction of future.

The professors have received $717,450 of support from the Mitacs Accelerate program and additional support from Smart Computing for Innovation (SOSCIP) in partnership with i-5O, an early stage Silicon Valley based start-up that has developed a proprietary computer vision powered digital twin to help manufacturers track, measure, and improve their manual production processes. Headquartered in San Francisco with operations in Toronto and Windsor, the company works with large Fortune 500 manufacturers in North America and Asia.

Khizer Hayat, chief innovation officer of i-5O, says its collaboration with Wu and Rahimi will bring the latest in artificial intelligence for improving human performance to the manufacturing industry.