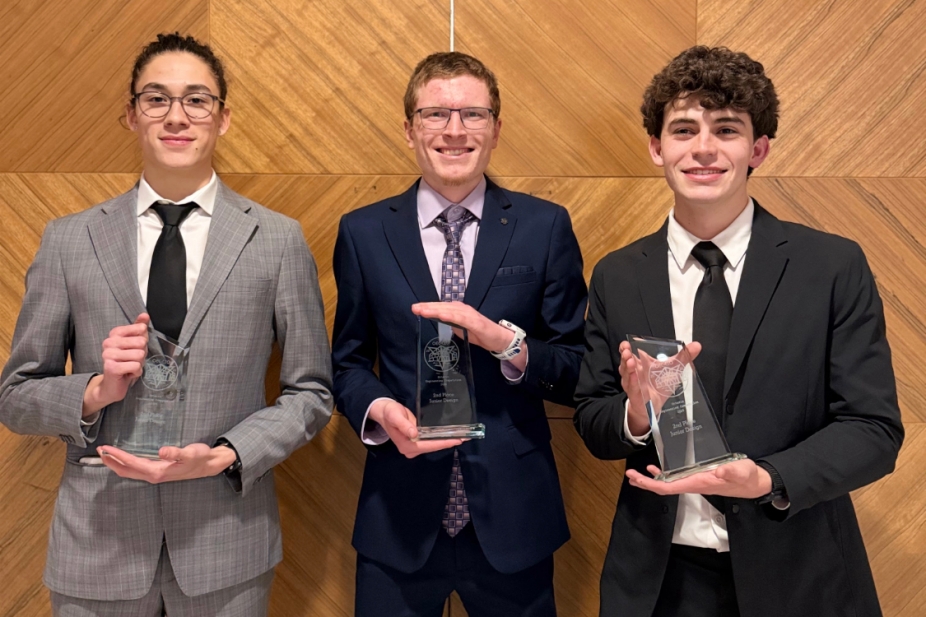

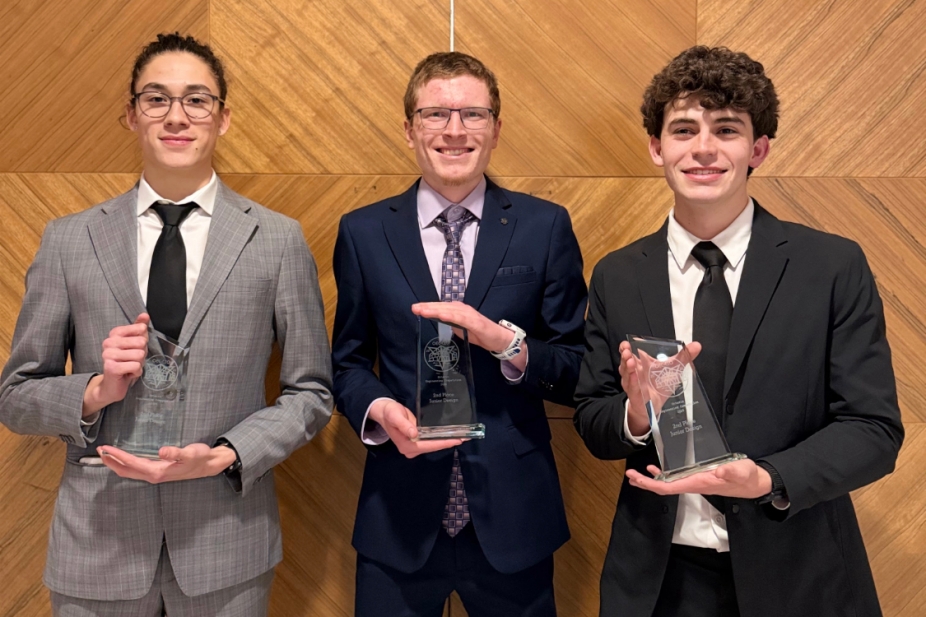

Second-year mechanical engineering students (from left to right) Kai Luong, Owen Lebel and Andrew Raoux secured second place in the junior design division at the Ontario Engineering Competition in Ottawa, Ont. (ANDREW RAOUX/ University of Windsor)

Second-year mechanical engineering students (from left to right) Kai Luong, Owen Lebel and Andrew Raoux secured second place in the junior design division at the Ontario Engineering Competition in Ottawa, Ont. (ANDREW RAOUX/ University of Windsor)

By Lindsay Charlton

After winning their home competition, three University of Windsor engineering students earned a second-place finish in the junior design division at the Ontario Engineering Competition in Ottawa.

At last month’s competition hosted at Carleton University, second-year mechanical engineering students Andrew Raoux, Kai Luong and Owen Lebel earned one of two qualifying spots for the Canadian Engineering Competition with a project that launched and safely landed an egg “astronaut.”

— Published on Feb 18th, 2026

More than 230 fourth-year students recited the University of Windsor Engineering Oath during the Faculty of Engineering’s Iron Pin Ceremony on Friday, Dec. 16, 2026. (KYLE ARCHIBALD/University of Windsor)

More than 230 fourth-year students recited the University of Windsor Engineering Oath during the Faculty of Engineering’s Iron Pin Ceremony on Friday, Dec. 16, 2026. (KYLE ARCHIBALD/University of Windsor)

By Lindsay Charlton

More than 230 engineering students pledged their commitment to integrity, respect and positive impact as they complete their final year of studies and prepare for the professional world.

— Published on Jan 27th, 2026

Dr. Dan Watt presenting the inaugural Dr. Daniel Frank Watt Scholarship in Materials Engineering to recipient, graduate student Amirmasoud Khodadadibehtash, at the University of Windsor on Wednesday, Dec. 17, 2025. (MIKE WILKINS/ University of Windsor)

Dr. Dan Watt presenting the inaugural Dr. Daniel Frank Watt Scholarship in Materials Engineering to recipient, graduate student Amirmasoud Khodadadibehtash, at the University of Windsor on Wednesday, Dec. 17, 2025. (MIKE WILKINS/ University of Windsor)

By Lindsay Charlton

Described as one of the “founding figures” of the Faculty of Engineering at the University of Windsor, Dr. Dan Watt is continuing his legacy through a scholarship for materials engineers pursuing research.

The inaugural Dr. Daniel Frank Watt Scholarship in Materials Engineering was awarded Dec. 17 to its first recipient, graduate student Amirmasoud Khodadadibehtash, during a celebration attended by Watt, his wife Linda Menard-Watt, faculty members and friends and family.

— Published on Jan 12th, 2026

Luca Mastroianni is a third-year mechanical engineering student at the University of Windsor and a participant in the Outstanding Scholars program. Through this placement, undergraduates gain paid research experience and work closely with faculty on innovative research initiatives. (Submitted by LUCA MASTROIANNI/University of Windsor)

Luca Mastroianni is a third-year mechanical engineering student at the University of Windsor and a participant in the Outstanding Scholars program. Through this placement, undergraduates gain paid research experience and work closely with faculty on innovative research initiatives. (Submitted by LUCA MASTROIANNI/University of Windsor)

By Victor Romao

Luca Mastroianni has always loved building things.

From welding and woodworking projects in high school to designing automated systems in university, his hands-on approach to problem-solving has shaped his academic journey.

— Published on Nov 25th, 2025

Kayes Reza, Dr. Rupp Carriveau and Under Sun Acres owner Chris DelGreco at Under Sun Acres in Leamington, Ont. (NAOMI PELKEY/The University of Windsor)

Kayes Reza, Dr. Rupp Carriveau and Under Sun Acres owner Chris DelGreco at Under Sun Acres in Leamington, Ont. (NAOMI PELKEY/The University of Windsor)

By Lindsay Charlton

From the University of Windsor’s Turbulence and Energy Lab to the greenhouse industry, a recent graduate is putting research into practice, tackling efficiency and sustainability challenges.

Kayes Reza (MASc ‘24) joined the team at Under Sun Acres, a Leamington greenhouse operation that uses advanced technology for sustainable solutions, as a cogeneration and heating system operator just weeks after graduation.

— Published on Nov 10th, 2025

Dora Strelkova took top honours in the UWindsor Three Minute Thesis competition with her presentation “You wouldn’t want a pie filled with holes, so why should we accept 3D printed parts with them?”

Dora Strelkova took top honours in the UWindsor Three Minute Thesis competition with her presentation “You wouldn’t want a pie filled with holes, so why should we accept 3D printed parts with them?”

A mechanical engineering graduate student took first place in the annual Three Minute Thesis competition with research that pokes holes in three-dimensional printing technology by exploring the flaws left in printed parts.

Dora Strelkova impressed the judges with her presentation, titled “You wouldn’t want a pie filled with holes, so why should we accept 3D printed parts with them?” Her thesis project, which she has been working on for the past two semesters, began as a new hobby she developed during pandemic lockdowns.

— Published on Jun 16th, 2025

Dr. Jill Urbanic, professor in the Department of Mechanical, Automotive & Materials Engineering and co-founder of CAMufacturing Solutions, sits in her lab at the University of Windsor, where she leads cutting-edge research in additive and hybrid manufacturing technologies. Her work is driving global advances in Industry 4.0, creating pathways from research to commercialization, and preparing the next generation of manufacturing innovators. (MIKE WILKINS/The University of Windsor)

Dr. Jill Urbanic, professor in the Department of Mechanical, Automotive & Materials Engineering and co-founder of CAMufacturing Solutions, sits in her lab at the University of Windsor, where she leads cutting-edge research in additive and hybrid manufacturing technologies. Her work is driving global advances in Industry 4.0, creating pathways from research to commercialization, and preparing the next generation of manufacturing innovators. (MIKE WILKINS/The University of Windsor)

Synergies between research and manufacturing industry leading to commercial impact for University of Windsor and its partners

CAMufacturing Solutions, Inc. is a Windsor-based company created from fundamental engineering research at the University of Windsor (UWindsor). Providing specialized software to program, simulate and interact with manufacturing systems, it has evolved into a firm with global reach; its software is today used in more than 47 countries.

— Published on Jun 16th, 2025

Doctoral students Shiva Nejati and Kunj Dhonde are part of a UWindsor research team working to make the vehicles of tomorrow safe from cyber attack.

Doctoral students Shiva Nejati and Kunj Dhonde are part of a UWindsor research team working to make the vehicles of tomorrow safe from cyber attack.

At the University of Windsor, two teams — red and blue — are locked in a strategic battle, working toward the same goal: safeguarding the future of automotive cybersecurity.

These teams, operating from the Automotive Cybersecurity Centre of Excellence, better known as SHIELD, are focused on opposing areas of security solutions for the auto sector.

With an eye on the future, SHIELD, the only centre of its kind in North America, has the goal of ensuring vehicles of tomorrow are safe and secure.

— Published on Jun 18th, 2025

Second-year mechanical engineering students (from left to right) Kai Luong, Owen Lebel and Andrew Raoux secured second place in the junior design division at the Ontario Engineering Competition in Ottawa, Ont. (ANDREW RAOUX/ University of Windsor)

Second-year mechanical engineering students (from left to right) Kai Luong, Owen Lebel and Andrew Raoux secured second place in the junior design division at the Ontario Engineering Competition in Ottawa, Ont. (ANDREW RAOUX/ University of Windsor)